Kohler Small Engine Flow Bench

Team Members

Stewart Daniels, Brendan Bloom, and Cody Eby

Advisor

Scott Wagner, Manufacturing and Mechanical Engineering Technology

Sponsor

Kohler

Project Overview

The field of engine design requires a wide variety of parameters to show the performance of an internal combustion engine. A very popular way to do so throughout the industry is with the use of a flow bench. A flow bench is generally designed to move air through cylinder heads or other components to measure the overall air flow throughout the entire system. The goal of our project is to assist Kohler's Engine Department in designing a new, highly accurate flow bench for small engines.

COVID-19 Decontamination Chamber

COVID-19 Decontamination Chamber

Team Members

Jacob Talaga and Dane Riha

Advisor

Scott Wagner, Manufacturing and Mechanical Engineering Technology

Sponsor

Department of Manufacturing and Mechanical Engineering Technology

Project Overview

Our team was tasked to transform an existing system into a self-contained decontamination unit. Decontamination will be achieved using heat, chemical spray, and UV light. This project aims to both create a working unit and design a kit that can be used to transform similar units for future pandemics. The project was passed on from a previous MET senior design team. Currently, our team is working on adding more modes of decontamination, adding ease-of-use systems, and writing code to control the systems.

Fluid Power Vehicle Challenge

Advisor

David Wanless, Manufacturing and Mechanical Engineering Technology

Team Members

Derek Flory, Erika Gabriel, Brittney Phillips, and Hunter Ransom

Sponsor

NFPA (National Fluid Power Association). There are several sponsors involved in NFPA. The largest sponsors are: Danfoss Power Solutions, Norgren, Parker Hannifin, Lubritech, Hydroforce, and IFP (Iowa Fluid Power).

Project Overview

The Vehicle Challenge supports the education of next generation engineers by exposing them to the design challenges associated with a fluid powered vehicle, and teaching them the value of fluid power components, circuits, and systems. In addition, the program provides these students with first-hand experience in working as an engineering team on a timeline to design, simulate, build, test, qualify, and compete with their concepts.

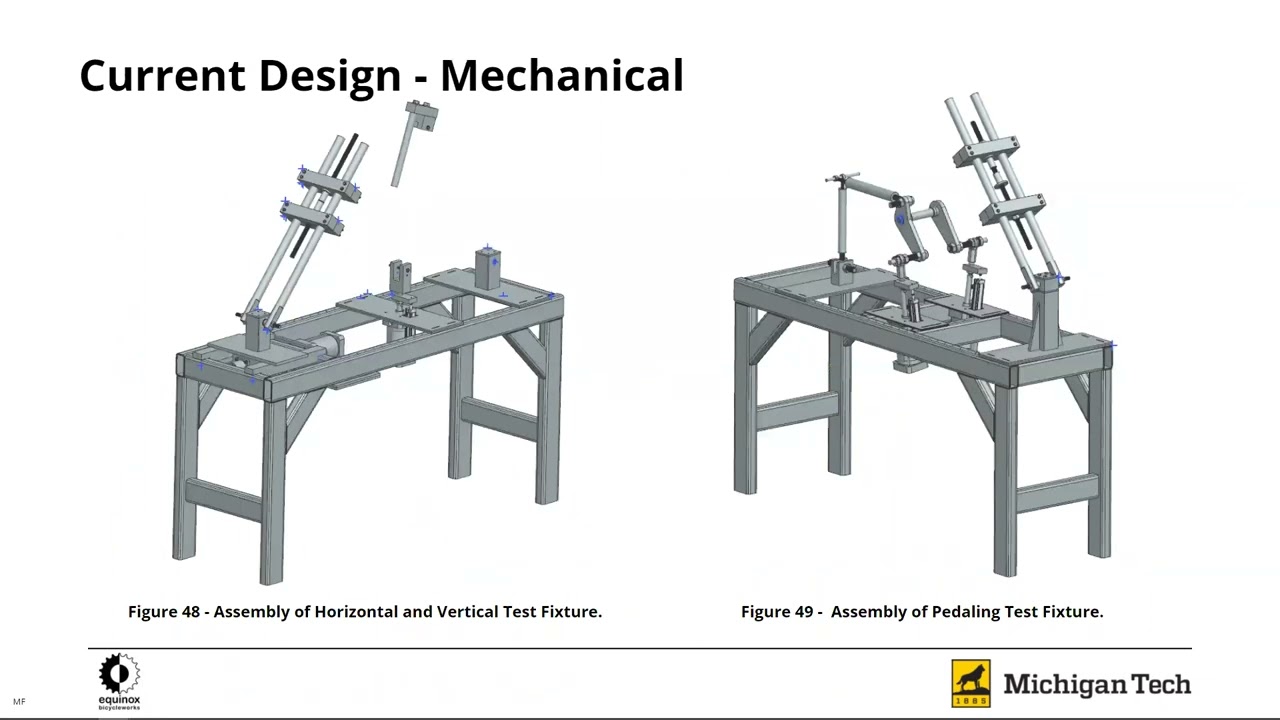

Bike Frame Fatigue Testing Stand

Custom Bicycle Frame Test Fixture for Fatigue Testing

Team Members

Joseph Williams, Brandon Kuhn, Mike Forrester, and Robert Sullivan

Advisor

Kevin Johnson, Manufacturing and Mechanical Engineering Technology

Sponsor

Equinox Bicycleworks and Engineering, Cleveland Cliffs

Project Overview

The overall goal of the custom bicycle frame fatigue testing fixture project is to deliver an all-inclusive system to verify frame performance under certain fatigue testing conditions, per ISO 4210-6 safety requirement standards. Our team provided a cost-effective solution for conducting an A to B comparison of bicycle frame designs with varying parameters. The fatigue testing fixture involves facets of many engineering disciplines, including mechanical, pneumatics, electrical, controls, and data logging.

Enterprise

Oshkosh Additive Manufacturing

Team Members

AME, Advanced Metalworks Enterprise

Hannah Wright, Spencer Butke, Zach Barrette, and Ean Salo

Advisors

David Labyak and Nick Hendrickson, Manufacturing and Mechanical Engineering Technology

Sponsor

Oshkosh