201: 3D Printed Tissue Mimic Material Characterization and Analysis

This project involves determining human tissue mimicry of 3D printed polymeric materials. Polymers are printed from Stryker's 3D Digital Anatomy Printer with the goal of using these polymeric materials for device testing rather than cadavers when possible. Our project focuses on completing a range of mechanical tests on a selected group of 3D printed materials, each with different ratios of the printer’s base inks. Then, mechanical characterization tests yield properties that differentiate the materials and allow our team to create a database and program for Stryker’s reference. We also conducted an investigative analysis of the trends between material properties and base ink ratios to ultimately create mechanically predictable material mixtures for better mimicking human tissues.

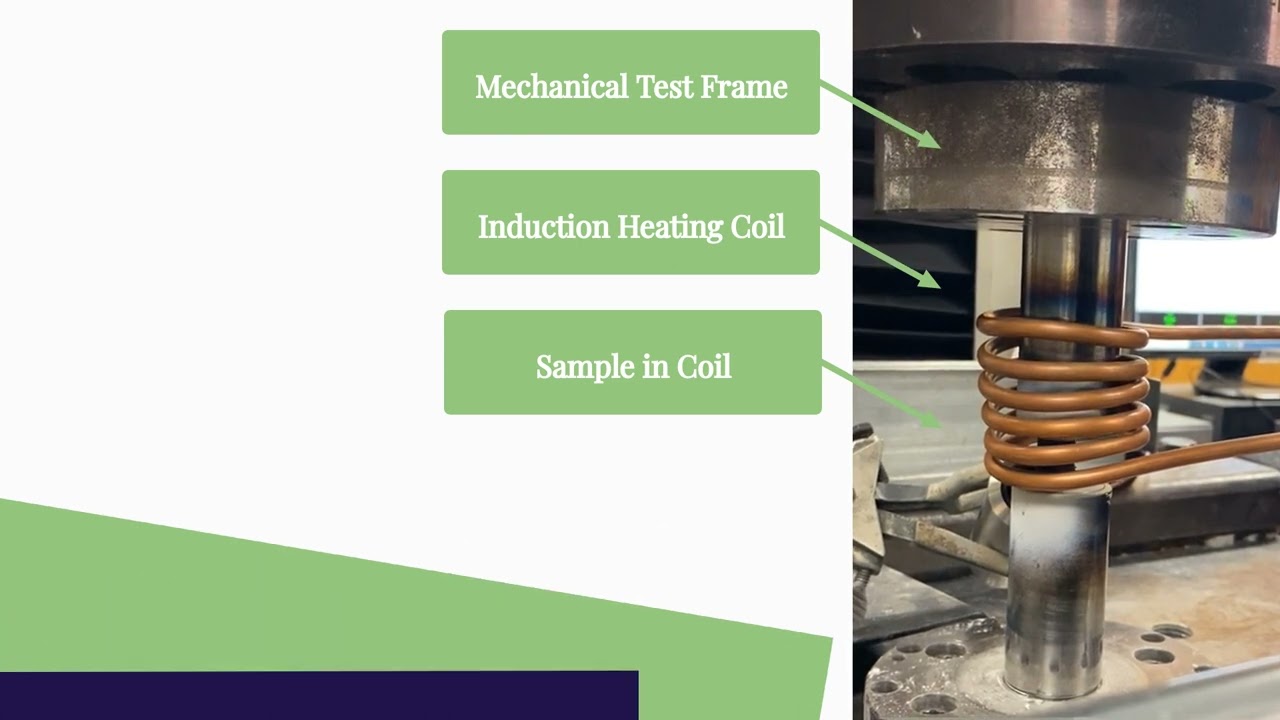

202: ArcelorMittal Wire Arc Additive Manufacturing Graded Structures

Our team was tasked with using wire arc additive manufacturing (WAAM) to print and characterize a low and high carbon compositionally graded structure. The implementation of dual wire feeding for a low-carbon steel core and high-carbon steel exterior will significantly reduce material cost during wire arc additive manufacturing and provide alternatives to machining large, high alloy steel tooling. For this project, hardware modification was necessary for simultaneous multi-material printing. Samples were printed, and thermal data was captured to characterize and predict microstructure and mechanical properties. We also created and validated a finite element model.

204: Bluetooth Attacks on Medical Wearables

The goal of this project is to test the possibilities of security vulnerabilities between the connection of an Apple Watch and an iPhone. This is relevant because Apple devices are the most popular fitness tracking device on the market, and research shows that Bluetooth is vulnerable to certain attacks. This is especially true with its counterpart Bluetooth Low Energy, which has recently been tested for its security. We are currently in our second phase, where we are testing connections with a multitude of tools.

205: Britten Water Filtration System

The goal of the project is to develop a portable water filtration system within a 10' shipping container utilizing renewable energy. The water filtration system contains a sediment depth filter, a water softener, a reverse osmosis filter, and a UV filter. Contaminated water enters the container and is filtered to NSF53 potable drinking water standards. Using either solar or shore power, the system will output 5,000 gallons per day while a PLC regulates the flow of operations. The team sponsor, BoxPop, powered by Britten, requested a finalized prototype design by the end of the year.

206: CAT Autonomous Lens Cleaning System

The purpose of this project is to develop prototypes that will effectively clean a Light Detection and Ranging (lidar) system and camera that have been chosen by Caterpillar. This solution is expected to be a foundation for Caterpillar’s further prototyping and implementation of an autonomous sensor cleaning system for their autonomous vehicles. The first semester involved project planning, ideation, research, and testing of our initial prototype ideas. The second semester involved further iterations of the prototype designs and testing and finalizing the design for delivery.

207: COVID-19 Decontamination Chamber

Our team was tasked to transform an existing system into a self-contained decontamination unit. Decontamination will be achieved using heat, chemical spray, and UV light. This project aims to both create a working unit and design a kit that can be used to transform similar units for future pandemics. The project was passed on from a previous MET senior design team. Currently, our team is working on adding more modes of decontamination, adding ease-of-use systems, and writing code to control the systems.

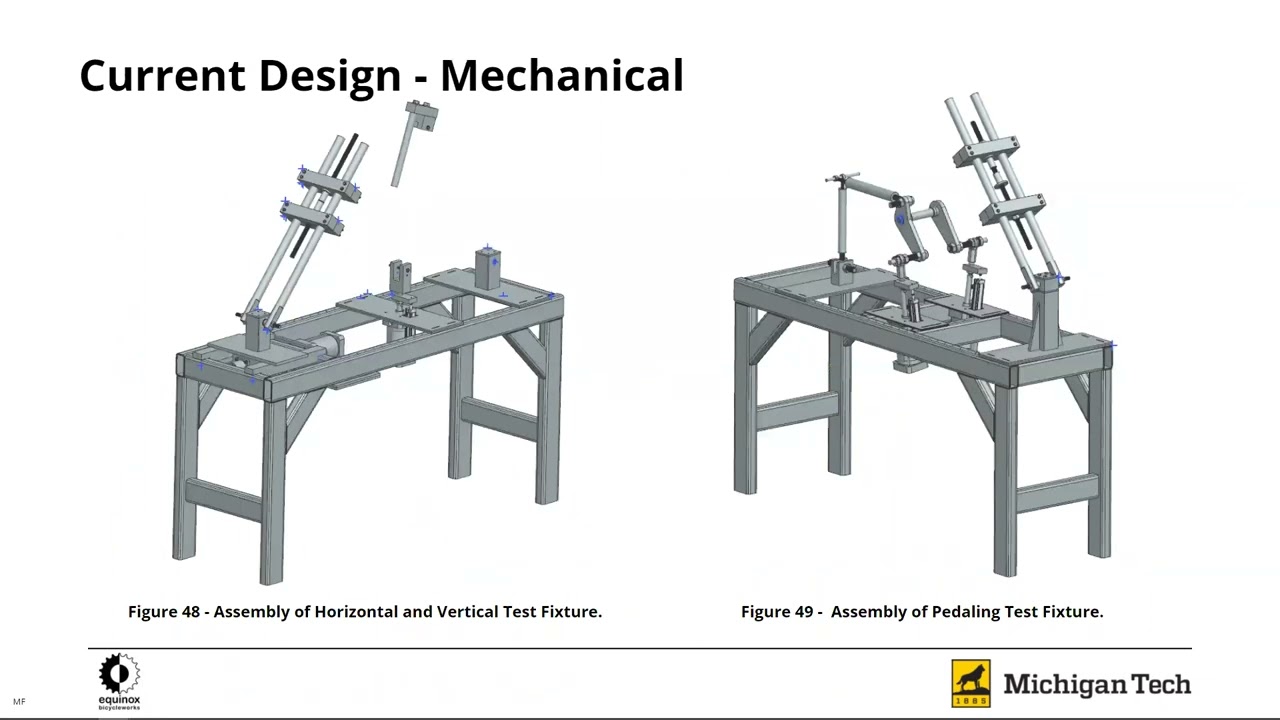

208: Custom Bicycle Frame Test Fixture for Fatigue Testing

The overall goal of the custom bicycle frame fatigue testing fixture project is to deliver an all-inclusive system to verify frame performance under certain fatigue testing conditions, per ISO 4210-6 safety requirement standards. Our team provided a cost-effective solution for conducting an A to B comparison of bicycle frame designs with varying parameters. The fatigue testing fixture involves facets of many engineering disciplines, including mechanical, pneumatics, electrical, controls, and data logging.

209: Custom Designed and Fabricated Dynamic Mechanical Analyzer Test Grips

The objective of this project is for the team of students to design and build a set of 3 prototype grips to help prevent slippage or tearing in the polymeric samples provided by Boston Scientific. Our team produced drawings and performed challenge testing on each design before bringing them to the sponsor to test on the RSA-G2 test instrument. Our goal for a successful outcome of this project is to create 3 prototypes with no more than 1 in 5 test specimens failing as a result of the grips slipping or tearing.

210: Cycle Time Improvements in Medical Device Manufacturing – Laser Welding

The goal of our project is to develop a strategy that simplifies and decreases the time required for loading both core wires and hypotubes into a laser welding cassette, making the handling of both components more convenient and efficient. We are developing an elegantly simple, channeled manufacturing aid customized to suit the operation's unique welding cassette. We are also developing a comb for hypotube organization under checkpoint cameras.

212: Drone-Based Crack Detection System

The goal of the Drone-Based Crack Detection System is to reduce the cost and risk to workers who are inspecting areas that may be unsafe. With the use of Intel RealSense, a Raspberry Pi, and Artificial Intelligence (AI), the drone will be able to detect and label cracks in infrastructure. The drone will send live video feedback to the user with a screenshot to save. This data collected will be used to train the AI continuously.

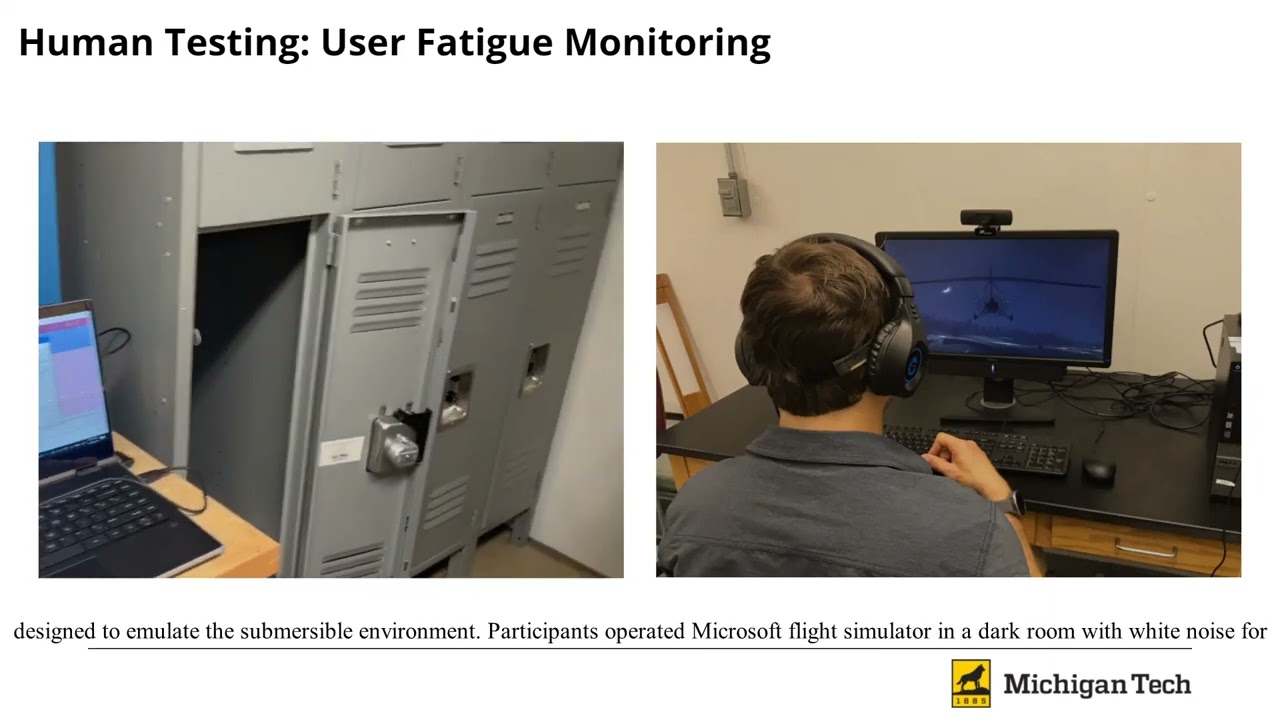

213: User Fatigue Monitoring System

Currently there is no system to monitor fatigue among naval pilots in submersibles. Our project aims to design a bio-feedback data collection and analysis system to quantify and assess pilot fatigue. This system will monitor and provide feedback to indicate when fatigue could impair normal function during long missions via heart rate variability (HRV). We performed human testing to evaluate the relationship between HRV and fatigue using small, noninvasive sensors. The team engineered a system that obtains biometric data from wearable devices and can be integrated into the existing technology of the submersible.

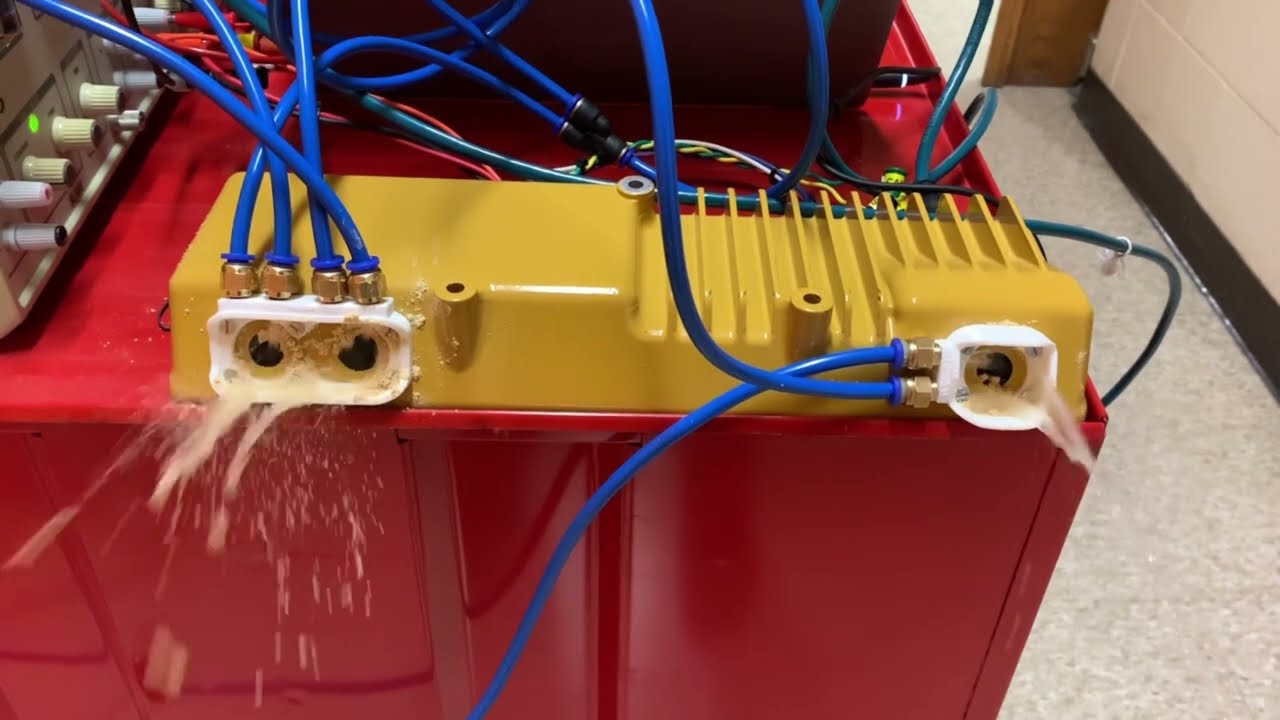

214: Durability Test System for Fluid Couplings

Our goal is to understand potential failure modes by creating a functional durability test system, and then cycling a variety of couplings and connectors provided by Colder Products Company (CPC) on flexible hose fittings. There is currently no functional test system to test the dynamic loads and the durability cycles that CPC connectors will encounter in the field. Our team developed a test system that includes the frame, force application, and data acquisition.

215: Economic Systems Analysis of Open Pit Gold Mine

Our team analyzed the economic potential of a southern California gold mine. We developed a systems model to represent project cash flow and will perform a sensitivity analysis to identify key variables. We used the model to assess how variability in the mining process affects the project's net present value, including revenue, operating costs, capital costs, and potential environmental impacts.

216: Emergency Situation Solar Generator

Our team was tasked with developing an affordable power source that can be resupplied via renewable solar power. The main purpose of this generator is to be deployed and used for communications and other low-voltage systems following extreme weather conditions that disable local power and disrupt the local energy supply chain.

217: Extremity Location and Movement Sensing for Movement Disorder Patients

The progression and severity of movement disorder diseases, such as Parkinson’s Disease and Essential Tremors, are typically measured by healthcare professionals using qualitative measures during discrete intervals of monitoring. This design project focuses on creating a sensor system that tracks and provides quantitative measurements of upper limb movement metrics–consisting of finger-tap frequency, supination and pronation abilities of the arms, and resting and active upper limb tremor frequency and amplitude–during in-clinic evaluations, in order to remove bias and enhance clinical outcomes. Our team designed the device prototype using IMU sensors integrated into an Arduino Nano system, which will monitor acceleration and triaxial motion to analyze patient movement and will compare results to individualized and established baselines.

218: Folding Entry Ramp and Step System for Medical Transportation Van Patient Entry

Little Brothers - Friends of the Elderly (LBFE) is a national network of non-profit volunteer organizations committed to relieving isolation and loneliness among the elderly. The Upper Peninsula Michigan Chapter helps accomplish this mission in a variety of ways, with one specific project being non-emergency medical transport assistance. With certain patients, mobility restrictions that require a wheelchair or walker can make transport time consuming and dangerous. The goal of the project tasked to Biomedical Engineering team 4 is to develop and deploy systems to ease the volunteers task and decrease the likelihood of dangerous outcomes, with focus areas such as a ramp and a portable step.

219: High Availability Cybersecurity Kit

Our team developed the High Availability Cybersecurity Kit (H.A.C.K.), a low-cost cybersecurity training kit for middle school and high school students. H.A.C.K. will introduce the concepts of networking, Linux, Raspberry Pi, password cracking, wireless attacks, and much more. Modules with tutorials will lead students through the activities with a focus on experimentation and exploration, hopefully lighting a spark of curiosity that could lead into a career in cybersecurity.

220: Hospital Washer AutoSampler Measurement Accuracy (Phase 3)

Our team was tasked with testing the accuracy of the wash time sampling prototype device developed by teams involved in Phase 1 and 2. The device is used to measure the washing of hospital tools. We are comparing the accuracy of the four separate sensors (PH, Conductivity, ORP, Temperature) against a higher-end industry standard to determine the accuracy of our prototype. The other half of our project involves creating an application that receives Bluetooth data sent by the prototype and graphs it in real time for easy visualization. The application provides the ability to review previous data graphs derived from saved CSV files.

221: Improving Consolidated Implantable Satellite Tag Retention Elements for Cetacean Conservation

Our team was tasked with modifying the retention elements of consolidated implantable satellite tags in order to improve retention time while minimizing tissue damage to the whale. This will allow the tags to stay implanted longer and transmit more data for the study and conservation of cetaceans. With the various retention element designs, our team performed retention tests using the MTS Acumen machine to measure the maximum force and total energy required to remove each tag. A tissue damage test was also performed using clay to show the damage caused by the retention elements of each tag during insertion.

222: IoMT Device Security

Our team researched the current security of Internet of Medical Things (IoMT) wearable devices. We have tested a wide selection of different smartwatches and accompanying smartphones for a number of different potential vulnerabilities. These include physical attacks, sniffing, man in the middle, dos, reverse application engineering, and more. The main purpose is to identify common weaknesses in security across this field, and to provide suggestions for mediation.

223: IoT Course Development for CNSA Curriculum

The goal of this project is to implement some topic that is not covered sufficiently enough within the CNSA curriculum. We first determined that topics surrounding the Internet of Things would be a sufficient topic. We then created ten labs, ten modules, homework, and a final exam for topics surrounding IoT, including data administration, IoT security and protocols, history, modern and future use of IoT, cloud and fog computing, analytics, and implementation of IoT. Upon completion of the modules we began a lab-testing phase to finalize our project. Currently, we are using IoT-based hardware including nest cameras, raspberry pi pico, and raspberry pi, to test security and implementation based IoT techniques.

224: ITC LEED Metering

The goal of our project is to find appropriate gas, water, and electric meters that can be used to collect data for ITC Headquarters in Novi, Michigan, as part of the company’s effort to become LEED certified. We conducted research onLEED and metering systems to find a system that meets LEED requirements and is cost effective, but also efficient. Then we made decisions on meter placement and meter types, in order to gain a full picture of a building's performance. This project is currently in its first phase and our team is developing different metering options for the ITC headquarters building for ITC to consider.

225: John Deere Portable Power Conditioner Phase 2

Our goal is to create a proof of concept of the safety of a portable power conditioner for John Deere's 8R line of tractors. The power conditioner system includes a Sine Filter, 3 Phase Transformer, and Solid State Relays (SSRs), voltage and current sensors. The control system is centered around an Arduino Mega micro controller with a Nextion Display to have user-selected voltage level outputs.

226: Kohler Small Engine Flow Bench

The field of engine design requires a wide variety of parameters to show the performance of an internal combustion engine. A very popular way to do so throughout the industry is with the use of a flow bench. A flow bench is generally designed to move air through cylinder heads or other components to measure the overall air flow throughout the entire system. The goal of our project is to assist Kohler's Engine Department in designing a new, highly accurate flow bench for small engines.

227: Land Assessment and Recommendations for the Carter Property

Our goal is to assess the current conditions of the Carter Property, a 107-acre parcel owned by Evangel Community Church, and propose potential uses of the land. The assessment was done through the use of geospatial software and equipment in conjunction with on-the-ground sampling at established points. Once processed and analyzed, the data were then used to generate future possible outcomes for the land - keeping in mind sustainability and the landowner goals/objectives - and the steps that could be taken for these outcomes to occur.

228: Landing System for Uncertain Terrain

The Psyche mission is a journey to a unique, metal-rich asteroid orbiting the Sun between Mars and Jupiter. What makes the asteroid Psyche unique is that it may consist largely of metal from the core of an early planet, one of the building blocks of our solar system. Our team is designing and prototyping a system capable of adapting to uncertain terrain on the Psyche asteroid. This system must be able to deliver a payload of three coinciding teams to the surface for an exploratory mission. Our team is currently determining the proof of concept for releasing the package through a rebounding action without need for anchoring to an unknown surface.

229: LBWL Distribution Protection Coordination

Our team was tasked with minimizing the impact of faults (such as power outages) on customers of Lansing Board of Water and Light (LBWL) and also minimizing financial losses caused by faults. The goal of our team is to research distribution protection schemes and devices to develop a methodology that can be used to evaluate and improve our sponsor’s current distribution networks. To determine the success and applicability of the methodology, we are using a cost benefit analysis to compare outage data, cost of equipment, and other sponsor-provided industry metrics.

230: Lear FEA Model of Electrical Crimp Connector for Automotive Applications

Our goal is to improve Lear Corporation’s FEA (finite element analysis) model, so that it can accurately represent the properties of an electrical crimp after a subsequent crimping process. Developing a model which can accurately predict material behavior for a given geometry and material properties would be beneficial to Lear Corporation, saving them time and money during the research and development of new crimping terminal designs. Major pitfalls in the FEA modeling process come from inaccurate representations of the material properties in the model, which leads to alterations of the final simulated crimp geometries after the subsequent crimping process. The major focus of this project is to determine the mechanical properties of crimp material and how they are affected during thermal cycling testing.

231: Locomotive Pinion Cutter Feed System

Our team was tasked with developing a safe, efficient, user-friendly field solution to the railway industry. This device uses an array of thermal lances to sever the pinion gear of a seized locomotive traction motor so the locomotive can move freely and not cause downtime or blockages on the railway. Ours is the fourth team to contribute to this project, and we are working to innovate and refine designs from the previous teams.

232: Lost Foam Casting Adhesive Development and Testing

Our team developed and tested an adhesive glue for use in lost foam casting. It must perform well as a glue, having low viscosity and an unharmful odor, and also thermally degrade at a rate similar to the EPS foam used as a pattern in the casting process. We are conducting casting trials with a glue that has been deemed acceptable in both qualitative and quantitative terms.

233: Material Characterization, Modeling, and Extrusion Optimization of Al-Ce-Mg Alloys

Our project’s goal is to gauge the viability of Al-Ce-Mg alloys for the application of commercial extrusion. These alloys have desirable room temperature mechanical properties that are retained at high temperatures. The main alloying elements, magnesium (Mg) and Copper (Ce), strengthen the alloy via solid solution and precipitate strengthening respectively; these different strengthening mechanisms will affect the flow stress of the material. Minimal research has been performed on these alloys’ flow stress behaviors and therefore the conditions under which they can be extruded. Through a series of hot compression experiments and calculation of sine hyperbolic inverse model flow stress parameters, we modeled the extrusion of three Al-Ce-Mg alloys using FEA modeling software Altair Inspire Extrude. This software allows us to compare the Al-Ce-Mg alloys to common commercial extrusion alloys, like AA6063, in terms of extrusion temperature, pressure, and speed.

234: MR Compatible Transseptal Needle with Integrated System for Confirming Left Atrial Access

We developed a working prototype for an affordable transseptal needle capable of confirming left atrial access via blood extraction and testing. We equipped the needle handle with NIRs technology that allows for the oxygenation of blood to be measured. We designed the needle so that it can be used in MRI-guided cardiac procedures requiring access to the left heart, such as cardiac ablations.

235: Mueller Brass Hollow Extrusion

Our team’s goal is to come up with a way to successfully produce brass hollows from a lead-free brass, C27450, using the process of extrusion. With the recent interest in using lead-free brass in the transport of potable water, there has been an increased demand for lead-free hollow tubing, however, lead-free brasses are very difficult to machine and produce a lot of material waste when being machined. Our goal is to reduce waste by utilizing extrusion, time, cost, and material.

236: Optically-Based Probe to Measure Tissue Oxygenation and Blood Perfusion

The goal of this project is to create a portable and non-invasive probe capable of measuring both tissue oxygenation and blood perfusion. These measurements help health care providers make quick and appropriate decisions when monitoring patients undergoing surgical procedures or recovering from a wound. Because of the lack of medical devices monitoring both values simultaneously, the problem is to design, develop and prototype a non-invasive optically-based probe that can gather blood circulation and oxygen delivery measurements that would help medical personnel recognize possible reduction and restriction of blood flow and of oxygen delivery.

237: Oshkosh Additive Manufacturing

Our team was tasked with finding optimized solutions for the manufacturing of suspension component geometries. The main purpose of this type of manufacturing method is to find different ways to produce lightweight parts for the best results, as well as print-on-demand replacement parts. This project is currently in its first phase. In this phase, the team is responsible for an industry and technology report, initial design review, and a proof of concept production.

238: OverDischarge of Medical Device Batteries

Our team sought to replicate and certify the validity of already performing tests on lithium-ion batteries, and to confirm or disprove claims that over-discharging the batteries has no negative effects on the user. We will study various groups of batteries, both medical and commercial grade, and run them through a performance, over-discharge, and recharge test, and a post-discharge performance test. After the tests, we will open the batteries and study their current collectors and electrodes under a microscope for corrosion products, finally interpreting our results in a scanning electron microscope.

239: PLC Data Wrangling and Backend Scheduling

We investigated areas of energy waste in a manufacturing setting alongside three other teams. Our team's goal was to be able to gather data from a machine's Programmable Logic Controller (PLC). The data gathered relates to what on the machine is currently running, idle, or off. This can include motors, pumps, and conveyors. The goal is to determine whether certain parts can be better switched on and off to use less energy.

240: Project Athena

The goal of this project is to help with the creation of a learning management system (LMS). Our team is split into two subteams–research and technical. The research subteam’s main tasks are market and user research through customer discovery methods such as conducting interviews with various end users. The technical subteam is using Adobe XD to design an automated grading pipeline. The subteams will come together to perform usability testing on the prototype design and collect user feedback to share with the client.

241: Rapid Corrosion Screening of Engineered Structural Fastener Coating Systems for Treated Lumber

The goal of the rapid corrosion screening project is to develop an accelerated test method using electrochemical impedance spectroscopy (EIS). The main purpose of this test is to screen fastener coatings for their likelihood to corrode in treated lumber. This project is currently in its third phase: statistical analysis of the data collected from the second phase–a full factorial design of experiment (DOE) of EIS testing and subsequent failure analysis–and any additional testing needed to solidify results. In this phase, our team is developing a method to accurately rank fastener coatings with respect to data provided by the sponsor and the results of the DOE performed.

242: Returning Samples of Hypothesized Surfaces

Our team was tasked with the design and prototype of a system for returning collected Psyche asteroid surface samples back to earth. The solution must consider the range of hypothesized surfaces and extreme terrain that might be found at Psyche, while keeping in mind other constraints such as its gravity. Hypothesized surfaces may include: mostly flat metallic surface, flat metallic with metal and/or rocky debris, rough/high-relief metallic and/or rocky terrain, high-relief metallic crater walls.

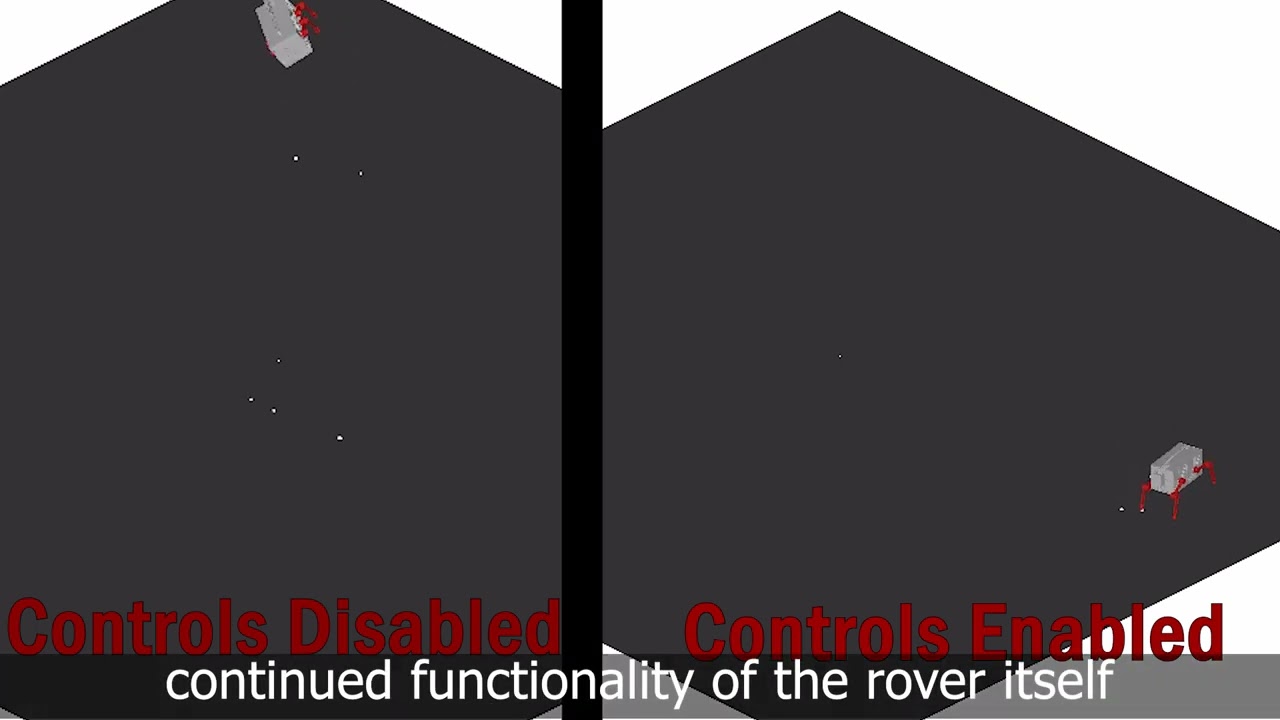

243: Robotic Explorer for Hypothesized Surfaces

The goal of the robotic explorer project is to design an explorer that can traverse the Psyche 16 asteroid between sample collection sites and a sample return system. As of right now very little is known about the surface of the Psyche 16 asteroid which means the robotic explorer needs to be able to traverse a multitude of different terrains. In the second phase of this project, the team is making simulations of the robotic explorer to show that it is able to make the desired movements to move across the asteroid, and designing a control system for the desired movements.

244: Sampling System for Hypothesized Surfaces

We have been engaged by Arizona State University (ASU) and NASA to design and prototype a sampling system capable of operating on the asteroid Psyche. It is imperative that the system can adapt to the hypothesized terrain and surfaces of Psyche, which include flat metallic or rocky surfaces, rough and high slopes of metallic and rocky composition, and crater walls. The system has a caching system for each sample to be stored within the design. Psyche is thought to be leftover material from a planetesimal, that is, one of the ancient rocky-metallic bodies that would have come together with others like it to become a planet. By studying it, we hope to be able to understand how Earth and other rocky planets may have formed in the early solar system.

245: Smart Switching — Power-Cycle Signature Acquisition for MacLean-Fogg Component Solutions

Our team was engaged by MacLean-Fogg Component Solutions (MFCS) to identify ways of reducing energy usage through machine idling in their manufacturing facility. We have been tasked with power data acquisition of older machines that do not use modern PLC technology. This has been achieved through collecting data using the PCE-PA Power Analyzer 8000, capable of collecting a variety of different current, voltage, and power measurements. In addition, we have developed a standard operating procedure (SOP) for ease of use as well as a VBA code. This code is capable of basic calculations and reformatting of the data for more efficient analysis.

246: Smart Switching – Scenario Simulator & Scheduling Frontend

We worked with four other teams to optimize power use by collecting data and switching off components, as well as identifying times where there are subcomponents that could be powered off. Our team is working on simulating power usage based on hypothetical scenarios.

247: Special Operations Forces Tactical Tools

Our team was tasked with creating a design to transport objects up to 100 yards over various terrains. The design is not to be fully ground- or drone-based, and may need to be used during intense battle situations. The design must also be backpackable, lightweight, and easily transportable. Our team’s final design uses a drone to carry a line, which is then attached to a highly durable dry bag container. The dry bag and line are then pulled in, delivering the needed objects to the person in need.

248: Stand Up Paddleboard Fishing Rod Holder

Our team set out to design an attachment to hold both the rod and the paddle during operation of the Stand Up Paddleboard (SUP). The activity of fishing on stand up paddleboards is growing, with a market need for an efficient attachment method that is compatible for all types of boards. It must also allow for simple attachment of the rod and paddle, and should not damage the paddleboard itself. Our design includes a unique mix of commercial off-the-shelf products and a custom-made base plate attached to the paddleboard via straps to meet the stated requirements.

249: Stromberg Carlson Electric Tongue Jack Redesign Phase 2: Application Development

Our team’s goal is to develop an android application that can communicate with the microcontroller of the electric jack. Commands include auto-level, retract, increment, and decrement. Our application displays angle values relating to both side-to-side and front-to-back views of the trailer hitch. This connection is facilitated over Bluetooth Low Energy 5.0. Furthermore, the application features a consumer-friendly design, created according to Stromberg Carlson branding. It possesses added features, as well, such as security pins, settings profiles, and safety checklists.

250: Stromberg Carlson Electric Tongue Jack Redesign Phase 2: Microcontroller

Our team’s project objective is to redesign an existing electric tongue jack, extending its functionality to implement “smart” features such as auto-level, return to hitch height, auto-retract, and jack actuation from a mobile phone application. Three subteams were formed to accomplish this task: a power electronics team responsible for creating a circuit capable of actuating the jack, an application team to develop the phone application, and a microcontroller team to design the electronic control system. As the microcontroller subteam, we are responsible for designing a custom printed circuit board, implementing control algorithms on a microcontroller to add the new “smart” features, and interfacing with the power electronic components and phone application.

250: Stromberg Carlson Electric Tongue Jack Redesign Phase 2: Power Electronics

Our team was tasked with redesigning the existing electrical components of the Stromberg-Carlson 4500lb Electric Tongue Jack to include new smart capabilities. This new design will incorporate Bluetooth functionality into the jack, allowing a user to raise and lower the jack using a smart device. Our team exists as a sub-team of the Electric Tongue Jack Redesign project, primarily focused on the power electronics aspect of the design. We produced a power electronics PCB capable of transferring 25 Amps of continuous DC current to the jack motor, detecting and routing fault signals, routing power to the microcontroller, and sensing the current through the jack load.

252: Thermal Processing of Aluminum Weld Wire with Scandium for Drawability

Interest in a strong but lightweight alloy has increased as companies attempt to find a substitute for steel alloys, specifically in the weld wire industry. One approach for this research is to add Earth transition metals to create new and more involved aluminum alloys. Previous experiments have shown positive effects on strength in the Al alloys with transition metals but with severely decreased ductility, leading to processing line failure. The goal of the Hobart thermal processing project is to identify an ideal billet heat treatment that will maximize the strength of an Al-Sc alloy but still retain enough ductility to allow for wire drawability as well as allow for full diffusivity in the welded product.

253: ThermoAnalytics, Inc. Advanced Battery Model Investigation

We were tasked with creating a testing system that can run standardized test profiles on battery cells that power hybrid and electric vehicles. We then used collected data to create new and improved models of the batteries following the National Renewable Energy Laboratory (NREL) Equivalent Circuit method. Once validated, we will couple the models with thermal modeling software developed by ThermoAnalytics, Inc., to allow for more accurate simulation of xEV's. This project is currently in its third phase. The lab setup is nearly complete, and official data collection has begun.

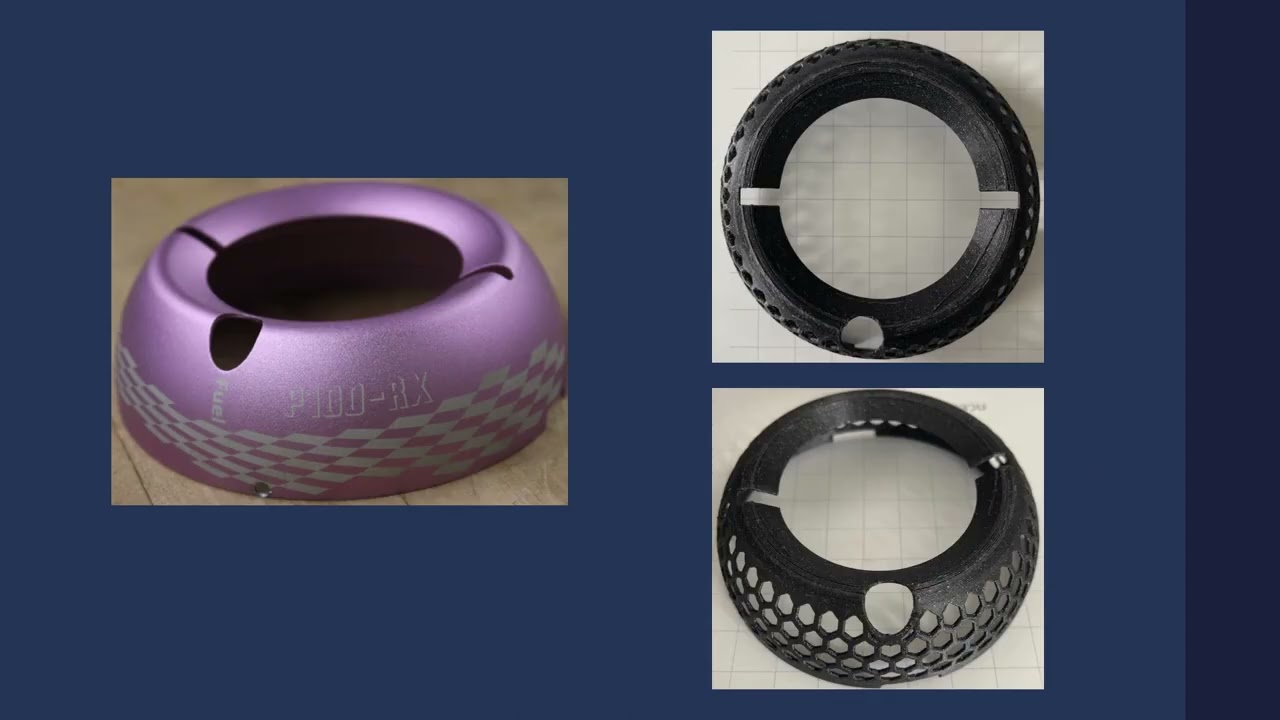

255: Turbine Engine Performance Improvement 2

Our team was tasked with increasing the thrust-to-weight ratio of a turbine engine without negatively affecting the thrust specific fuel consumption, or the thrust and propulsion efficiencies. We made modifications to the material of the inlet cowling and nozzle, as well as making changes to the nozzle geometry.

256: WarDriving IoT

Our project is composed of two focused subgroups: Offensive Red Team and Defensive Blue Team. The goal for Red Team is to utilize IoT hardware and complimentary open-source software to perform penetration testing on a network. Phases of Red Team’s project will include detection, intrusion, and attacking devices on a network while keeping cost to a minimum. The goal for Blue Team is to utilize IoT hardware and software to defend a network. Blue Team’s focus is set up in three phases: basic network setup, advanced user setup, and network lockdown. Each phase will incorporate different levels of configuration and introduce new IoT devices and software to help monitor and defend against Red Team’s attack vectors.