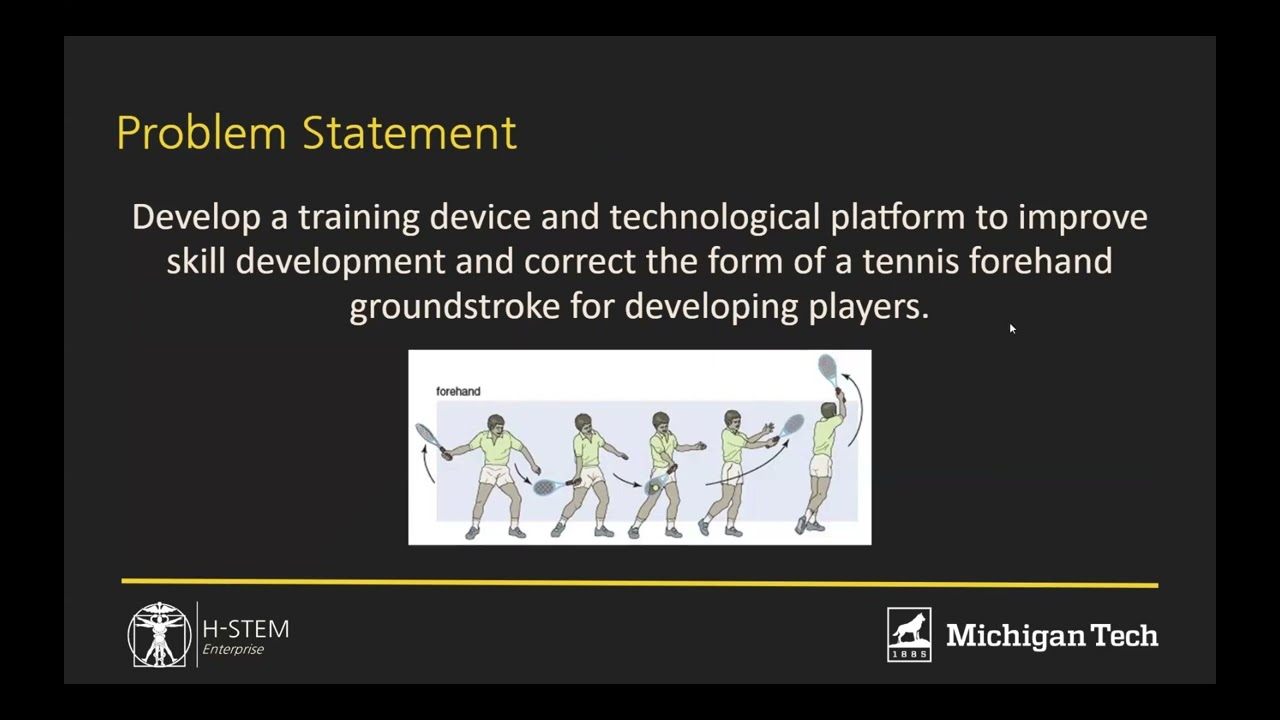

301. Athletic Performance Assessment Device

Our goal is to develop a wearable training device and a paired technological platform that will enable developing players to improve skill development and correct the form of a tennis forehand groundstroke. The device is intended to correct and optimize form as well as prevent injury due to incorrect form or overuse. Introduced this semester, this project is in its very early stages of development. We are currently conducting initial sensor concept testing with an Absolute Orientation sensor.

303. Clean Diesel - Generating Biodiesel from University Wastes

Our team will analyze and convert used soybean oil from campus dining halls into usable biodiesel fuel to provide a second life to waste oil. The produced biodiesel can be blended with petroleum diesel for use on campus and within the Houghton community. During past semesters previous teams working on this project have studied reaction chemistry to optimize the reaction needed to make biodiesel. Currently, our team is working on implementing a commercial biodiesel processor in the Chemical Engineering Unit Operations Laboratory. This would provide senior chemical engineering students with experience in the food and oil industry prior to graduation.

304. Koppers In-Line Chemical Analysis

Our team is working to develop an in-line chemical analysis sensor. This sensor or series of sensors will need to measure a high concentration of ammonia, copper, and carbon dioxide in an aqueous stream. The plant we are partnered with for this project measures these concentrations through laboratory procedures that are time-consuming and slow. The overall goal is to streamline the process to free up laboratory labor and create a higher quality and more consistent product.

306. OneTumbler Multi-Use Beverage Container

Our team aims to encourage sustainability on Michigan Tech’s campus through promoting a multi-use beverage container made from recycled plastic. Our goals are to generate awareness and investigate new market opportunities for the OneTumbler product line. The high-level approach to achieving greater levels of sustainability at Michigan Tech is through reducing the amount of single-use beverage containers on-campus. The main objective of this academic year is to complete a life cycle assessment comparing the OneTumbler to single-use paper coffee cups and plastic water bottles. Additionally, the team will conduct leak and drop testing on the OneTumbler. Note: the OneTumbler Sustainability team is a subteam of the CPM Enterprise.

307. Prosthetic Compatibility Device

Current prosthetics are inefficient to manufacture and fit, causing pain due to increased force on pressure points on the stump and friction between the stump and the prosthetic. Oftentimes, prosthetics must be remanufactured to find a comfortable design. The prosthetic compatibility device team aims to develop, design, and test a device concept to increase fit compatibility by improving the accuracy of the current fitting process. Our team has completed background research, performed multiple interviews with members of industry, polished our device concept, and are now entering a prototyping phase.