201. Accelerometer Sensing Pack

The goal of the Accelerometer Sensing Pack project is to develop a small device that can record acceleration data at a specific resolution for a minimum of one week. The device must be battery powered and all data collected must be power safe. The purpose of the device is to allow Kimberly-Clark to be able to test how shock and vibrations affect their products. To complete this project, the team has designed a printed circuit board with a microcontroller, accelerometer, and memory device as well as written and tested code for the microcontroller to be able to collect accelerometer data and store it in a way that can be viewed later.

202. Ambulatory Connection Device for Preclinical Studies

The objective of this project is to create an animal vest and cable system that will permit continuous data collection and drug delivery without interfering with animal and environment care. The device will allow the large mammal (goat, pig, dog, sheep, etc.) to freely ambulate around the enclosure while being able to withstand normal wear and tear of daily use. The resulting design will be made available online to both the medical device and pharmaceutical industries to aid in large animal research for product development. Currently, there is no such design that allows for both effective data collection/drug delivery and ambulation of the animal that is readily available for use by industrial R&D organizations.

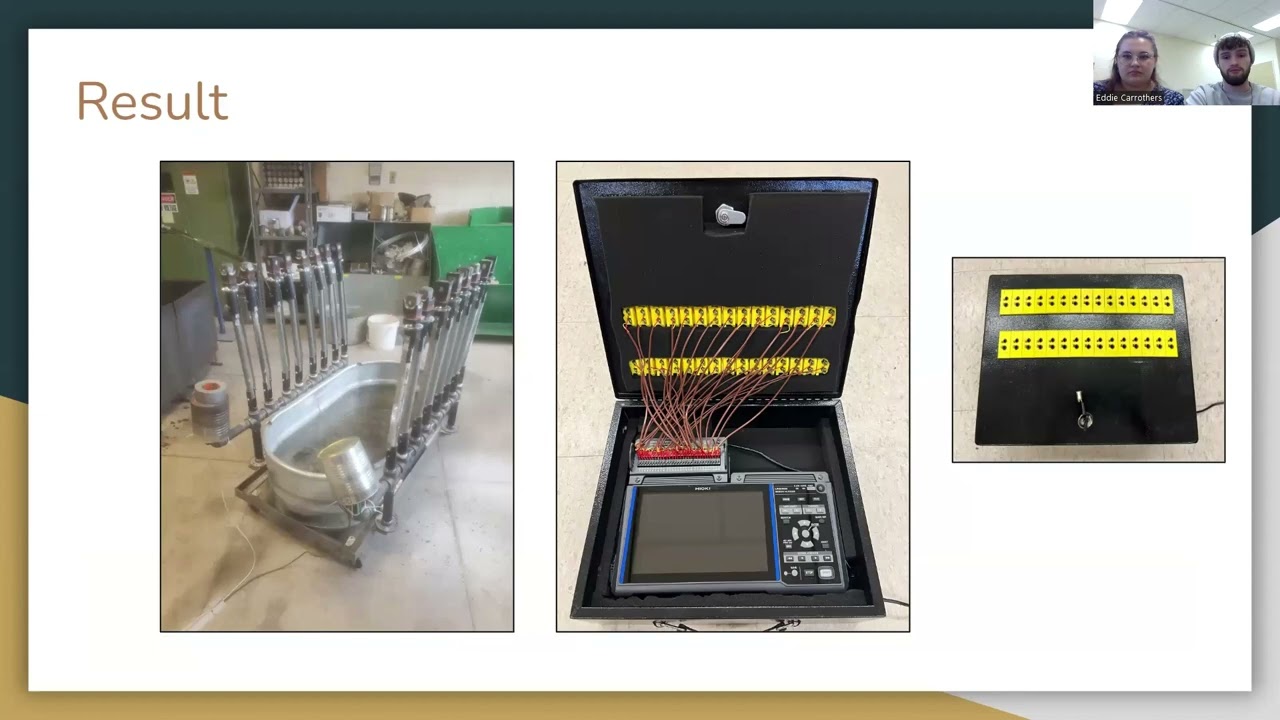

203. Automated Data Collection in a Foundry Environment

The goal of this project is to set up an automated data collection system for the MTU foundry. This system will need to be simple to use, hard for users to make a mistake, and able to withstand the foundry environment. Along with doing all the necessary research to find a data logger that would meet the requirements of the customer, we set up quick settings so the program would be easy to use and code that would automatically take the recorded data and output it into an Excel document of measurements and visual graphs for each thermocouple. We also came up with a secure carrying case for the data logger along with installing electrical ports on the side so the data logger could be used without needing access to the physical device, thus limiting the possibility of it being damaged.

204. Body Mounted Sensors-Aircrew

The goal of this project is to develop a system to be worn by aircrew during their daily activities that can record baseline physiological data in a secure manner for comparison to in-flight data. The physiological parameters of the design the team focused on include respiration rate, heart rate, and body temperature. The team was also tasked with quantifying activity intensity.

205. Calculation of radiation view factors via high-performance ray tracing on HPCs and GPUs

The goal of the view factor calculation project is to research, implement, and evaluate a few third-party ray tracing libraries. The main purpose of the resulting data is to inform TAI of possible performance enhancements that could be made to their current view factor calculation software. Currently, the team is working through the final phase of the project, which includes running benchmark tests on the two libraries against TAITherm and collecting and analyzing the results.

206. Cybersecurity Law - Digital Rights and Privacy

The goal of the Cybersecurity Law project is to create and submit a data rights and privacy bill to the Michigan legislature. The basis of the law will be derived from an analysis of existing bills of other states and related resources. An initial document will be crafted with regard to the research and the group’s outlook on what should be a part of a potential law. Then after contact with members of the legislature, the document will be fleshed out into a proper format for a bill. Afterward, the bill is to be introduced to the legislature, with the hope it becomes state law.

207. "Day in the Life on the Moon"

Multi-Mission Consumable Analysis of Regolith Filters for NASA’s Artemis Program

The MTU Systems Engineering senior design project aims to pinpoint a gap in NASA’s Artemis program and propose a solution. Our identified gap involves reducing cargo mass and designing a process for multi-mission consumable use. We focus on lunar regolith filters. Our team is developing qualitative and quantitative models for filter lifespan analysis, consumable re-usage feasibility, and traceability from campaign to component requirements. Utilizing Model-Based Systems Engineering (MBSE), we will deliver an analysis and documentation highlighting the gap identified in NASA’s current lunar mission plans.

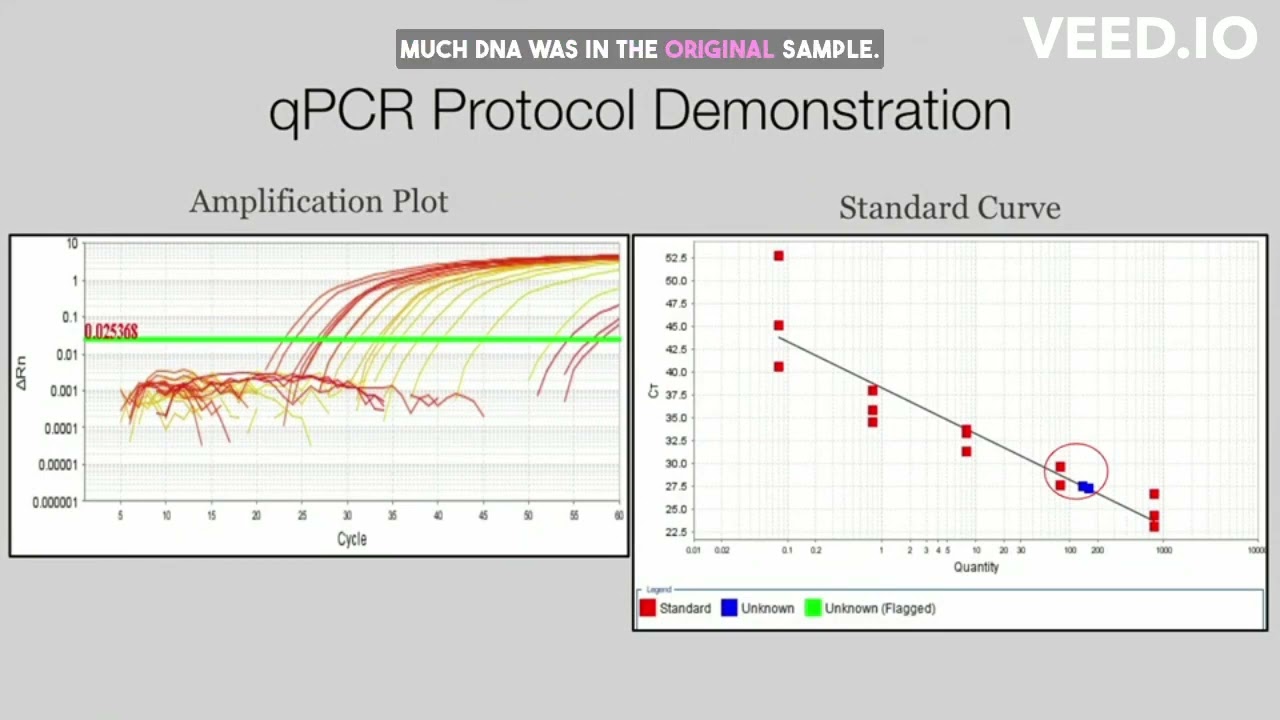

208. Development of a qPCR Assay for Clinically Relevant Bacteria Used in Chemical Disinfection Confirmation Testing

This project aims to replace the current method of disinfection validation using quantitative polymerase chain reaction, or qPCR. The present method uses agar plating and counting to quantify an unknown bacteria concentration in a sample. The device is cleaned, and residual bacteria is collected and plated for measurement to validate disinfection methods. The main objective is to create a new set of unique primers and probes for each of the five bacterial strains the team is working with, to eventually allow for multiplexing multiple strains at once in the qPCR machine.

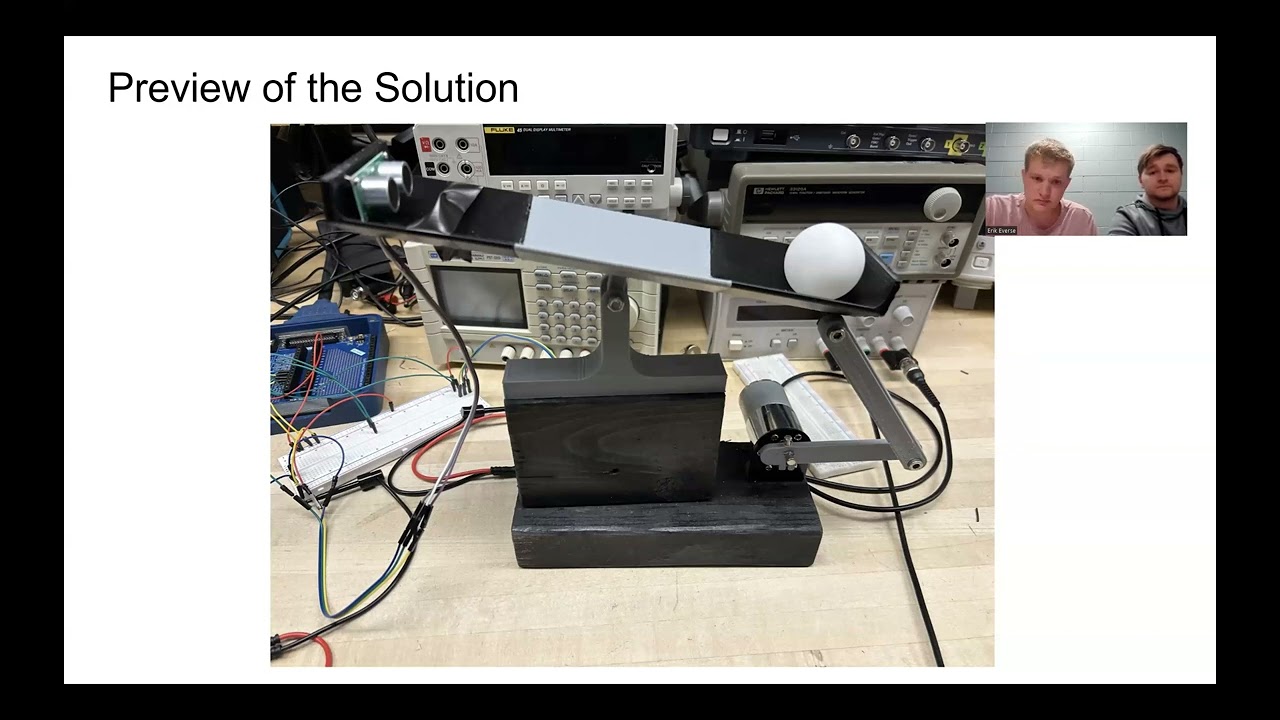

209. Development of PID Tabletop Training System

The goal of our project is to fix the lack of hands-on labs provided in EET 2150 and EET 4311. We are seeking to develop a lab that can be placed on a tabletop and give students an opportunity to see the effects of PID controllers. This lab will be utilizing a DC motor that will control a teeter-totter in order to balance a ball in the middle of the teeter-totter.

210. Device to Culture Anterior-Segment of the Eye and Measure Intraocular Pressure in Real Time

At present, animal models are frequently employed to assess novel corneal disease treatment options, such as drug delivery, corneal wound healing, and regeneration. However, this reliance on animal models raises ethical concerns. Furthermore, these animal models might not accurately predict how drugs or regenerative processes will occur in humans. Evaluating regenerative medicine strategies with donor human corneas could improve the success rate of regenerative treatments. Thus, this project aims to develop a device which can be used to culture the whole anterior segment of the eye, which includes cornea, and provides the ability to measure changes in intraocular pressure for up to two weeks or longer. During the development phase of the project, rabbit eyes will be used as a model.

211. Gratiot Road Bridge Replacement Design

The Gratiot Rd Bridge Project aims to design a replacement bridge structure across the Cooper Drain in St. Clair County. The final design will be designed in a way to minimize construction time and traffic disturbance on Gratiot Rd and also update the bridge's geometric design load rating to meet AASHTO regulations. Other considerations include HECARS water flow modeling and projected increasing traffic flows.

212. Industry 4.0

The goal of the industry 4.0 team is to update several systems in the foundry at MTU to industry 4.0 standards. This means updating all of the processes involved in collecting and receiving data. The focus of this project is on data centralization as the final goal is to have all of the new systems implemented into one environment where data can be pulled from any computer in the foundry. Some of the new systems that are to be implemented include the Digitemp wireless temperature recorder, cameras to record foundry processes for educational purposes, computer replacement and repair, and an upgrade to replace existing data loggers.

213. Internet Of Things Dashboard

Our project streamlines IoT device management by consolidating data from distinct device types into a unified dashboard. It allows users to build out modularly and utilize import packages to denote more specific device types and commands. This eliminates the need for system administrators to navigate multiple proprietary platforms for monitoring. By pulling standardized information and statistics from each device and assigning specific tools for specific device types, our solution offers a comprehensive overview, enhancing efficiency and simplifying monitoring processes. This consolidated approach facilitates quicker decision-making and ensures a seamless management experience for information technology administrators.

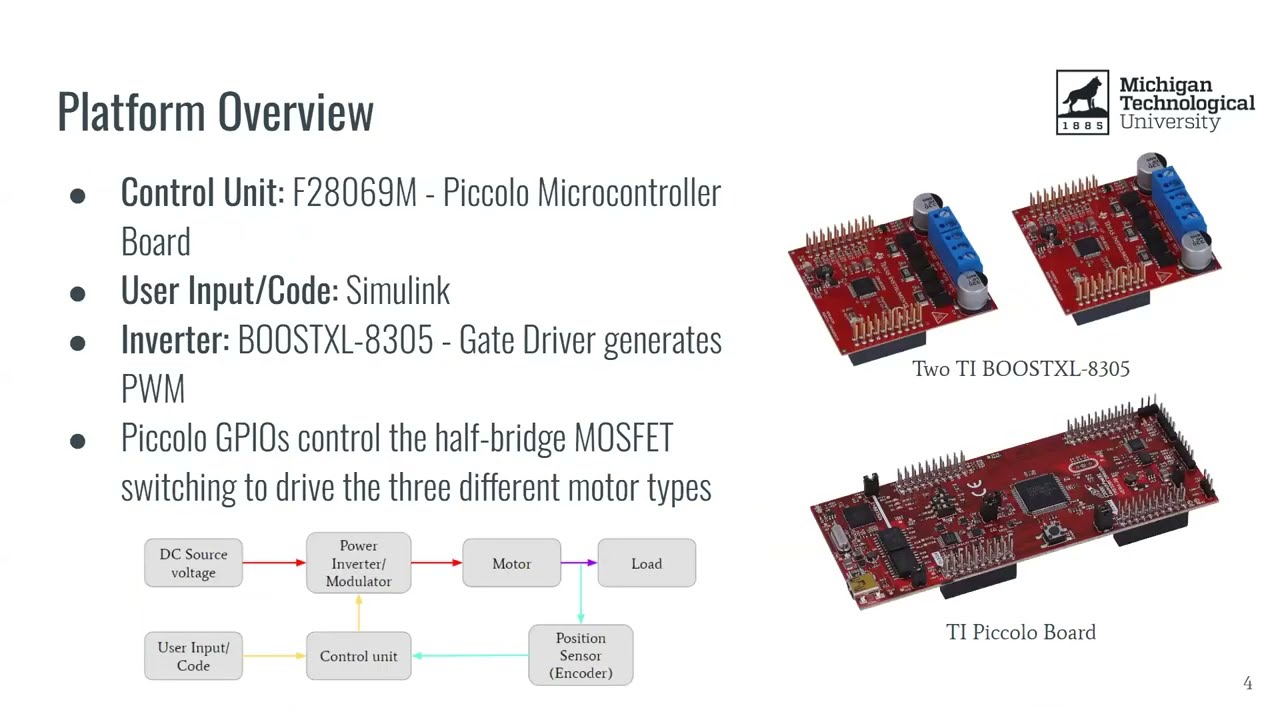

214. Low Cost Motor Controller

Michigan Technological University’s Electrical and Computer Engineering Department has a need for a portable and modular motor drive system, our team is continuing the work done by the last year's senior design team. This system should be equal in functionality to the current in-lab motor drive unit to demonstrate the capabilities of the department’s power labs, Power Electronics and Electric Machines and Drives (EE4228 and EE4220). Such a system can be built upon a microcontroller development board for a low-cost. The team's primary goal is to develop a low-cost and portable alternative tailored for the SB35 lab and beyond. The solution leverages the Texas Instruments LaunchPad and motor control BoostPack.

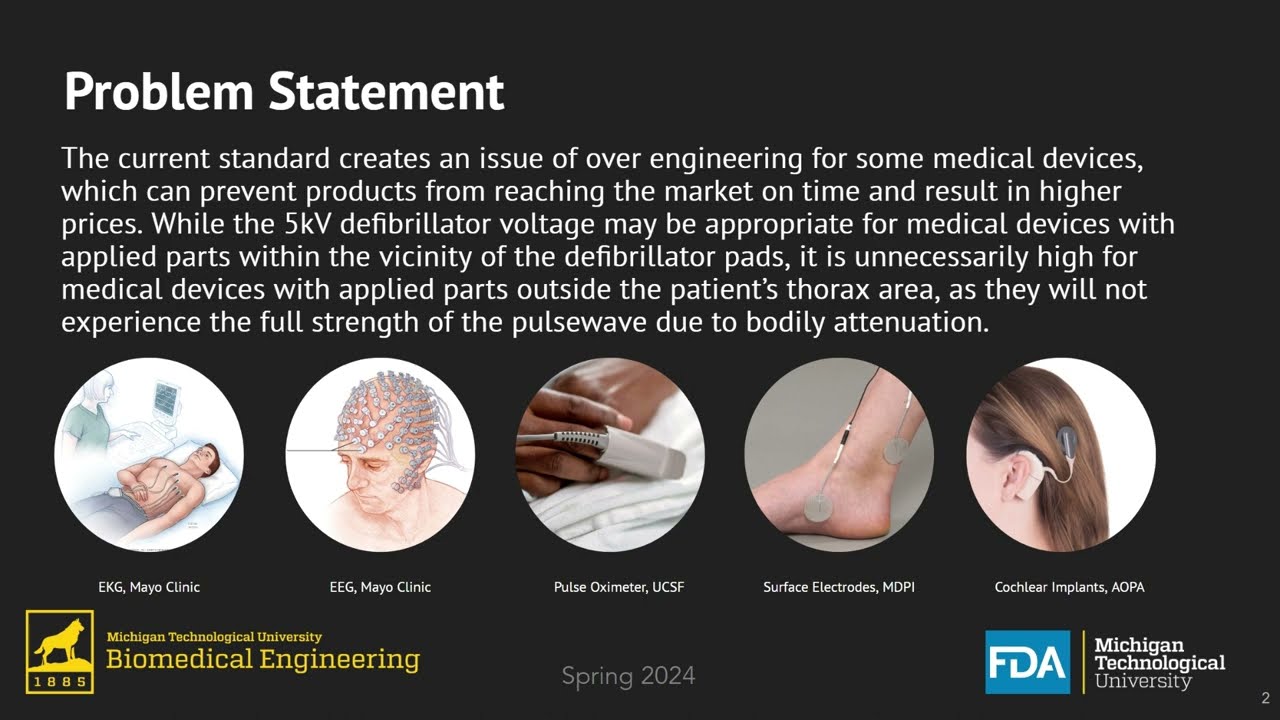

215. Mapping Defibrillation Pulse Attenuation

The current standard creates an issue of over engineering for some medical devices, which can prevent products from reaching the market on time and result in higher prices. While the 5kV defibrillator voltage may be appropriate for medical devices with applied parts within the vicinity of the defibrillator pads, it is unnecessarily high for medical devices with applied parts outside the patient’s thorax area, as they will not experience the full strength of the pulsewave due to bodily attenuation. The goal is to design a human impedance simulation model to provide an accurate representation of the attenuated defibrillation strengths at locations on the body.

216. Mechanical Properties and Microstructure of Gray Iron with Boron Contamination and Removal by Soda Ash

In gray iron, boron is an undesired contaminant that has adverse effects on mechanical properties. Soda ash has been shown to effectively reduce boron levels when added to molten gray iron. Further study was needed to understand the effects soda ash has on microstructure and mechanical properties. The goal of this project is to understand and quantify those effects. From cast samples, both with and without soda ash addition, tensile testing and hardness data were collected. Microstructural effects were analyzed as a function of cooling rate using modular step block castings.

217. Microstructural and Mechanical Effects of Reducing Hafnium in MAR-M247

MAR-M247 is a nickel-based superalloy, which is used in high-temperature applications such as gas turbine engines. Hafnium is used in MAR-M247 as it forms stable high temperature carbides that are useful in retaining strength in these high-temperature environments. However, hafnium has drastically increased in cost over the last few years and has a tendency to cause cracking during pour solidification. Howmet Aerospace, which produces components made of MAR-M247, is interested in reducing the weight percent of hafnium. Using simulation software, compositions of varying hafnium levels have been cast into test bars. These will then be assessed via microstructural analysis and mechanical testing to verify that the mechanical and casting properties are maintained or improved.

218. Minimally-Invasive (MIS) Cable Passer for Trauma Surgery

The goal of the minimally-invasive (MIS) cable passer for trauma surgery project is to develop a MIS cable passer that allows for fracture stabilization in trauma surgery, specifically for long bone injuries. MIS surgeries are done to reduce incision size, limit exposure to potential infections, and reduce both nerve damage and muscle atrophy; all of which enable a shortened recovery time when compared to the current standard that utilizes large incisions for fixation. The project is currently in its design development phase which has included: preliminary research, defining constraints, objectives, and specifications, concept development, CAD modeling, design selection, design iterations, exploration of potential manufacturing processes utilizing 3D printing techniques, and testing.

219. Molecular Monitoring System

The goal of this project is to create an integrated circuit that can measure and transmit data from a specific collected analyte to a smart device. The circuit will be integrated with a custom electrochemical biosensor to be attachable and detachable. The device will utilize a high-resolution ADC and control amplifier to enhance the small input signal for analysis, and then using a Bluetooth Low Energy Module transmit that data wirelessly to a smart device for display. The completed circuit board will be constructed to fit within the size constraint of a bottlecap and be capable of collecting, analyzing, and storing data to be transmitted wirelessly to a smart device.

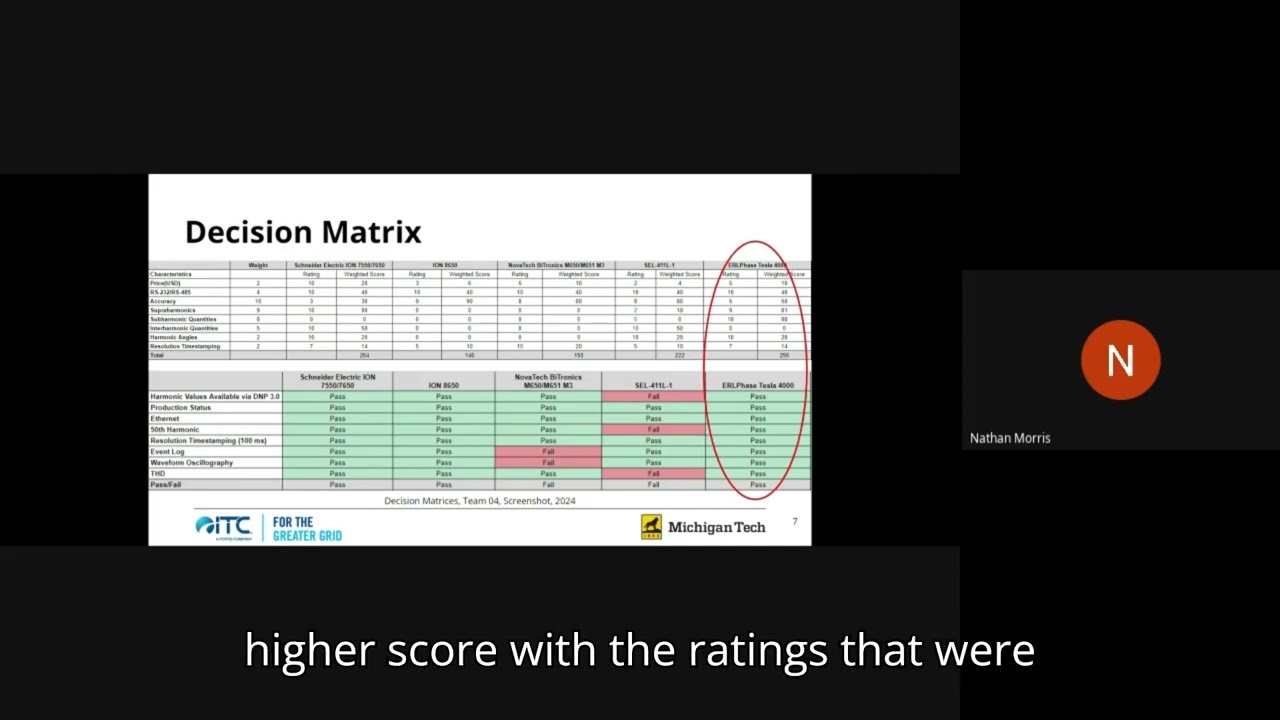

220. Monitoring Harmonic Distortion Levels in Power Systems

The monitoring harmonic distortion in power systems team was tasked with developing a system of devices that could be used to monitor increasing levels of harmonic distortion in the United States' power systems. The team aimed to use devices that are standard to the sponsor, ITC Holdings, to avoid increased costs associated with the project. The project uses an ERLPhase Tesla Digital Fault Recorder to collect data on voltage and current, then a NovaTech Remote Terminal Unit to process the data. When determined that an alarm is necessary, an alert is sent to the ITC Holdings control room for operators to handle the issue.

221. Network Acquisition & Merge

For our project, we first plan to stand two networks up independently. These two networks will simulate the company MDI and the company being acquired, WCI. We will create these two networks with the equipment supplied by Heartland Business Systems. The networks will consist of server hosts, VoIP phones, and utilize a core/access network architecture.

After the independent networks have been created, we will then initiate the migration. The end goal being seamless communication across both networks under one administrative body. The network will be protected with a Next-Gen Palo Alto Firewall.

222. Optimizing Aluminum Extrusion Texture for Improved Bendability

The goal of the aluminum extrusion texture optimization project is to investigate ways to increase the cubic texture of 6005A aluminum and to study its correlation to bendability and energy absorption. The purpose of this project is to increase the safety to both the battery and passengers of electric vehicles in side impact collisions. This project is currently investigating the effect of homogenization treatment and the effect of composition on texture and bendability.

223. Optimizing Performance and Cost of Rail Grindstones

The grindstone project aims to develop a mixture and processing strategy to produce abrasive cutting materials for the rail grinding industry. The main purpose of this product is for the preventative maintenance of railroads, increasing their lifetime and reducing unnecessary outages. This project is currently in its mixture development phase as the processing for the production of the material has been largely completed. In the current phase, the team is developing a composition for the stones to optimize both grinding performance and cost.

224. Plasma Table Redesign

The goal of the Plasma Table Redesign team is to restore and improve the longevity of the MET Machine Shop plasma table. At the beginning of the project, the plasma cutter exhibited shaking during movement, rendering precise cutting operations unattainable. The original design was prone to premature failure, therefore our team was tasked with finding a more robust design. The scope of our project includes designing, manufacturing, and installing our solution.

225. Production Torque Test System for Medical Robot Accessory

The goal of Senior Design Team 10's project is to design, construct, and test an end of the production line torque tester system for a medical robot accessory. The system will ensure the devices under test are able to withstand a brake torque of 3 oz-in for 3 seconds without a notable change in rotational speed, which is a requirement of the devices before they exit the production line. Deliverables of the student team include a fixture to stabilize the device under test, a containment box to enclose the system, a PLC code to run the test, and other features of automation to allow for a more efficient test.

226. Project Puma: PPE Communication Improvement

Project Puma aims to improve communication between medical personnel while wearing the Stryker T7 helmet and personal protection equipment (PPE) during surgery. The designed communication system utilizes a microphone, amplifying bandpass filter, and bone-conduction headphones to increase speech intelligibility without wireless communication between headsets. The microphone collects sound from the operating room (OR) to be filtered by an amplifying bandpass filter. The bone-conduction headphones then transfer the filtered sound safely and hygienically, allowing the end-user to hear human speech and medical instrument noise, increasing the speech intelligibility between end-users.

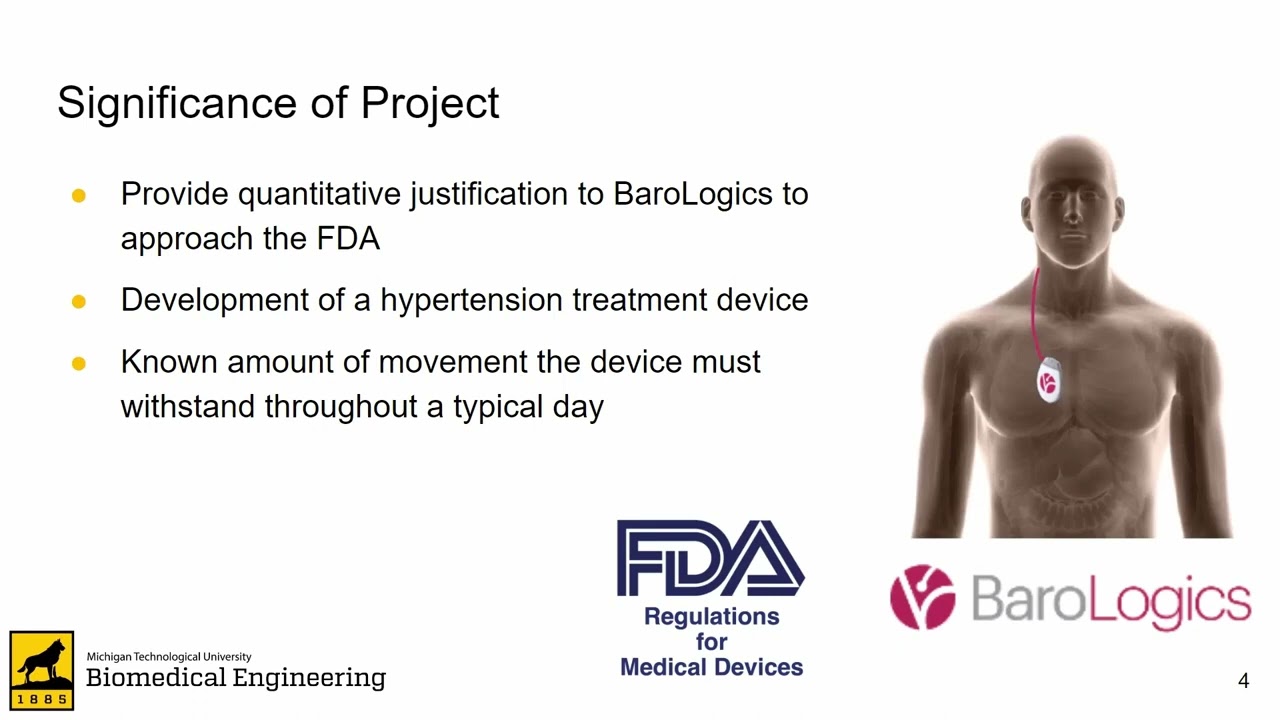

227. Quantifying Head and Neck Movements Over a 12 Hour Period

The goal of the Quantifying Head and Neck Movements Over 12 Hours project is to develop an instrumentation system to be used in human testing that will track a participant's head movement in degrees. The purpose of this is to understand how far and how frequently the head moves during daily activities, so the proper lead can be chosen and tested by Barologics. The project created a system with two fusion 9-DOF sensors and a Raspberry Pi Zero W to track the movement, which was binned out in post processing to find the frequency of movements in degrees.

228. Reducing Manganese Content in Solid Steel Weld Wire

The goal of the Hobart senior design project is to reduce the manganese content in solid steel welding wire to conform to OSHA requirements while maintaining mechanical properties of the wire. During the welding process manganese fumes are produced from the heat and these fumes can cause brain damage. Five steel compositions have been cast and are now in the manufacturing stage of the project, which includes rod rolling and wire drawing.

229. Republic Mountain Lake Renewable Energy Substation Evaluation

The objective of the Republic Mountain Lake Senior Design Team is to develop a 138/34.5 kV substation at the Republic Mountain Mine site, which will be integrated with the Alternative Energy Enterprises (AEE) renewable energy generation system. This substation aims to facilitate efficient and sustainable power generation to the residents of Republic and the Upper Peninsula of Michigan. The design is to be used by Republic Mountain Lake LLC. as they consider building a renewable energy facility at the Republic Mountain Lake location.

230. RFID Integration with Mobile Devices

The goal of our project is researching a way to add a student ID card onto your personal phone. This will then allow you to unlock doors that students have access to. With this we are focusing on how to create a lock that will work with newer phones, NFC built in devices, and an application to add IDs to. We are currently on our final part of the project of building out our test lock and programming automation scripts to use the door lock.

231. Rubber Tire Asphalt Design for County Road 573 in Dickinson County, MI

The goal of the Rubber Tire Asphalt Design project is to recommend a rubber tire asphalt mix design that provides the longest life expectancy for an asphalt overlay of an existing county road. The goal of the project is to recommend a mix design for a 1.5" asphalt overlay on a 3.14 mile stretch of County Road 573 in the town of Norway. Additionally, a project estimate will also be created. The mix designs tested were a modified HMA 5EML at 22% and 30% rubber content. The mix designs were tested for stability, rutting, cracking, cold weather susceptibility, and shear strength.

232. SecureCAN: Enhancing Cybersecurity in Connected Vehicles

Connected vehicles rely on the Controller Area Network (CAN) bus for communication between various components such as controllers, sensors, and the infotainment system. The CAN bus is known for its vulnerabilities to Cyber Attacks. Such as: tampering, data breaches, unauthorized access in connected vehicles. Goal of this project is to develop a Cybersecurity solution to protect CANBus data and ensure the safety and privacy of vehicle occupants and/or components.

233. Siemens Programmable Logic Controller Trainer Kit Development

This project delves into the development of our Siemens S7-1200 Programmable Logic Controller trainer kit that is aimed at enhancing training for introductory industrial automation. Some traditional training modules are due for a revamp to continue with the development of modern and efficient training tools. As such we have developed this project to focus on integrating both existing and new hardware components such as push buttons, lamps, motors, and fans. The main goal is to provide hands-on, practical training that mirrors real-world applications to bridge the gap between theoretical knowledge and practical skills in PLCs. By incorporating elements of interactable hardware and software the training kit aims to prepare future engineers for the challenges of modern industrial automation.

235. Real-time Hazard Evaluation and Mitigation Instrument (R.H.E.M.I)

Our MTU ECE Senior Design Team is participating in the SICK LiDAR Challenge. For this challenge, our team must utilize SICK’s Multiscan100 LiDAR in our own unique design project. Our design team has proposed a R.H.E.M.I, or Real-time Hazard Evaluation and Mitigation Instrument, relying on tactile pressure points to alert the user of nearby potential hazards. Along with the LiDAR, the device is utilizing an NVidia Jetson Nano processor, several actuators, and vibration pads to warn the user of nearby obstructions and hazards to carry out the device's intent.

236. Waterfowl Retrieval System - Fowl Fetcher

The goal of the waterfowl retrieval system is to provide hunters with a safer alternative to using hunting dogs. The robot needs to be able to safely locate a dead duck and return it to the hunter with minimal outside control. Currently the project has a working platform of a robot that can traverse different types of terrain easily. The focus for this phase of the project is to integrate GPS tracking, image recognition, and improve on last year's design.

237. Waupaca Foundry Automated Cast Cleaning

The goal of the Waupaca Foundry Automated Cast Cleaning project is to take a cast metal part with complex internal passages and autonomously remove all core sand from the passages. The project should also include the ability to verify that the passages are clear of any blockages. These processes are to be developed entirely by the team as there is no manual process for clearing or inspecting the passages due to the size and configuration of them. This project will allow Waupaca Foundry to enter several parts into production and ensure quality to their end customers. The team is currently developing the processes for both decoring and inspecting the parts individually.

238. Battery Electric Vehicle Front Bumper System

Steel has long been the material of choice for automakers. The primary objective of this project is to demonstrate that steel, with its broad palette of grades, remains the logical choice for the execution of mass efficient, cost effective, and sustainable designs for future battery electric vehicles (BEVs) and to dispel the myth that the only road to vehicle weight efficiency is through the use of alternate materials. Our project requires the Tesla model 3 front bumper system to be made entirely of steel, rather than the currently used aluminum model (datum). Our steel design must be equal to or lesser mass, attain better performance standards, cost less, and remain in the same design envelope as the aluminum datum.

239. Quench Box for an Extrusion Press

This project pertains to Shape Corporation. The team is tasked with helping Shape develop a quench box using large scale equipment while hammering in certain design parameters centered around pressure, temperature, and time. The team bought, fabricated, and tested a lab scale quench box to help with Shape Corp. requirements. The team needed to build a quench box as Shape was having trouble with dislocations at different points throughout the part prints, as well as having control on the water temperature used to spray the part and the rate at which the part is cooled.