201: Additive Manufacturing of a Steering Knuckle

With the development of metal 3D printing technologies in recent years, metal parts can now be quickly prototyped using additive manufacturing methods. Our team was tasked to design, manufacture and test a steering knuckle for Oshkosh Defense. The part is designed to be made of titanium and will be manufactured using a powder bed fusion process. A steering knuckle is a component that transfers the movements of a steering wheel to the front wheels.

202: Anaerobic Digestion System Design for Fabrica De Mezcal

Our team developed an anaerobic digestion system capable of converting the waste streams from mezcal production into biogas. The main purpose of the digester is to treat the toxic byproducts from mezcal production so they do not pollute the environment. This system will be sized and a cost analysis applied to design this system, in order to determine reliability and meet regulatory standards at the lowest cost.

203: Anatomical Characteristics, Simulation, Design and Test Development for an Implantable Pulse Generator (IPG) and Lead

We are determining the anatomical characteristics, simulation, design and test development of an Implantable Pulse Generator (IPG). Our project goal is to determine the lead pathway for the electrode anchored to the SCM, from the carotid bifurcation to the implanted device in the chest. We are investigating relative motion between the muscles in the neck to help find the most optimal pathway for the lead.

204: Audio Enhancement for Smoke and Carbon Monoxide Detectors

Traditional smoke and carbon monoxide detectors will emit an audible “chirp” when the battery goes below a certain voltage. It is often difficult to determine exactly which smoke detector is making this chirp. Our team’s goal is to create a smoke detector that will emit its own unique sound when it reaches the low voltage threshold, this way it will be very easy to determine exactly which smoke detector in the building needs to have a new battery.

205: Automated Vacuum Control for Thin Film Deposition

Our project goal is to automate the process of operation of the vacuum machine that controls the thin-film-deposition chamber in the MFF facility lab. The vacuum machine is used to bring the atmosphere level in the main chamber down to vacuum pressure, or up to atmosphere pressure. The process is currently completely manual, time-consuming, and confusing for first time users. Our work is focused on creating a new control system that is efficient and user friendly, with a touchscreen graphical user interface. The control system will be enclosed in an electrical box consisting of an Arduino Mega board, a signal conditioner PCB, a relay module, and a power supply.

206: Biobenefication—Civil Design

There are various methods for mineral extraction from lithium ores. Flotation is a commonly used beneficiation process of lithium. Recent research has shown that Gram-positive rhizosphere bacterium, Paenbacillus poloxyma, produces a bio-surfactant that eliminates many of the issues associated with the flotation process. It can also be used to change the settling properties of similar minerals like quartz and mica, which allows for an easier extraction of spodumene. Integrating the use of this bio-surfactant into the lithium extraction process reduces, or eliminates entirely, the need to use chemical depressants associated with fatty acids, high intensity agitating, and heat-treating.

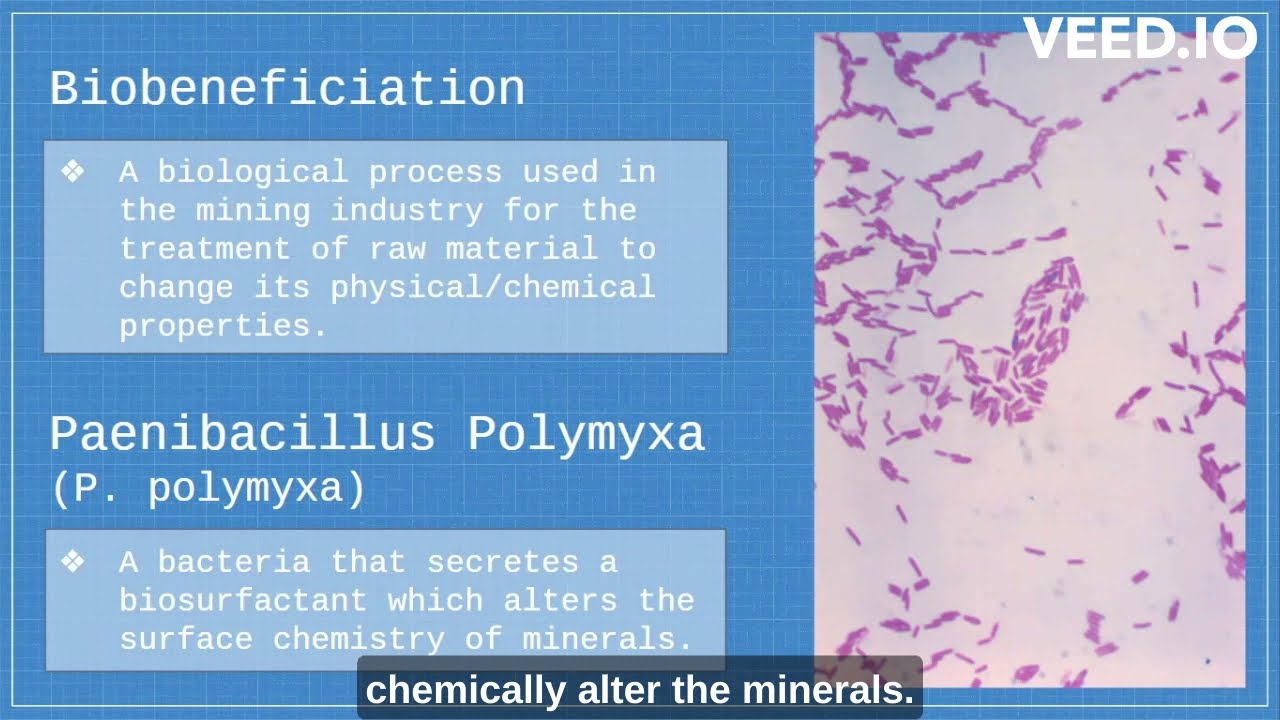

207: Biobeneficiation as Pretreatment to the Flotation of Pegmatite Ore

Pegmatite ore, which contains lithium, is currently processed in the U.S. using flotation methodology. This process is inefficient and ineffective due to the similar densities of minerals in the ore. The goal of this project is to design a pretreatment process to improve lithium recovery. Biobeneficiation as a pretreatment to flotation has been shown to significantly improve the retrieval of a desired mineral. Biobeneficiation uses a biological agent to separate the desired mineral from the ore. In this case Paenibacillus polymyxa (P. polymyxa) is used to isolate lithium from pegmatite. P. polymyxa produces a polysaccharide which alters the surface chemistry of all minerals, enacting enough transformation to allow for selective separation during flotation.

208: Bioreactor For Degradable Metal Assessment in Vascular Applications

The goal of the project is to design and construct a bioreactor where degradable alloy coronary stents can be tested for degradation under physiological conditions. These conditions include: heart rate, cardiac pressure waveforms, temperature, and flow rate. This project will allow for novel stent alloys and designs to undergo preliminary testing for degradation patterns and rates. This project is in its second phase. In this phase the team will conduct degradation experiments using the system to compare to the data collected from the static experiment performed in phase one.

209: Body Mounted Sensors

The goal of this project is to create a complete system, using commercially available sensors, to measure physiological parameters of fatigue and stress during physical activity. The system displays the physiological state of the user to a non-medically trained viewer. We selected sensors to measure core temperature, blood pressure and blood oxygenation, arrhythmia, and dehydration, respectively. We performed validation testing on the hydration sensor and additional intra-team testing to obtain data for analysis with the developed program. The program extracted data from the sensors to determine when the user has abnormal values, based on literature researched values, and displays the information in a friendly user interface.

210: Camper Security and Ambient Light Device

Our team developed a device that connects to a standardized 7-way RV plug, allowing the lights on the RV to be controlled by a Bluetooth-enabled device, such as a mobile phone. Our device enables lights to be controlled by a variety of features such as personal control, day/night schedule, musical light shows, and person detection. The project is currently in its third stage. During this stage, our team is working on creating a functional PCB and enclosure that would be ready to sell to consumers.

211: Cascade Chiller

Our project goal is to build a cascade fluid chiller that will accept a fluid from an external process and cool it to cryogenic temperatures as low as -122 F. This type of chiller has demand in both lab environments for cryogenic storage as well as other chemical processes requiring cryogenic temperatures. We are seeking to improve upon reliability issues associated with an auto-cascade system currently on the market.

212: Circular Bio-Based Fuel Spill Cleanup

A fuel spill on the corner of Highway 41 in the summer of 2021 rendered an area of the Portage Canal unusable for over a month in the heat of the summer. This project seeks to quantitatively analyze the spill and design different options for circular, bio-based, and sustainable cleanup of fuel spills. In collaboration with Hotforest Enterprise, the majority of the materials used in these solutions will be from waste products or sourced from animal wastes to facilitate a circular bioeconomy demonstration.

213: Cyber Law in the U.S.

The goal of our project is to develop a bill specifically for the state of Michigan that addresses shortcomings that exist in current U.S. cyber laws. It follows a similar format to the California Privacy Rights Act (CPRA) and incorporates ideas from the European Union's General Data Protection Regulation (GDPR). The bill is currently in a draft stage.

214: Design of a Method to Characterize the Depletion Mode Medical Device Battery - Phase 2

Our project goal is to perform electrical and physical characterization of medical lithium-ion secondary batteries when exposed to overdischarge for varying cycle lengths.

215: Developing a Climbing Assistive Exoskeleton

Our team’s paper presents a design of a climbing assistive exoskeleton (CAE) that reduces stress and strain on the fingers of a climber. Climbers routinely must support their entire body weight with their fingers. While human hands can accommodate climbing, experienced climbers are continuously testing the limits of their bodies, and hand injuries are both a frequent and severe occurrence . This device will help injured mountain climbers to continue training with reduced impact to their hand, and in turn increase climbing endurance and duration. Along with experienced climbers, inexperienced climbers suffer from a lack of finger and hand musculature. This device will aid them in training safely and learning proper grips while developing the musculature they need to be successful. The CAE is a glove-like device which can be slid on over the user's hand while climbing.

216: Device to Measure the Mechanical Properties of Cell Monolayer

This project sought to develop and test a methodology for determining the mechanical properties of a cell monolayer as a collective unit. The design consists of three crucial components: 1) growing a cell monolayer across multiple materials, 2) removing initial scaffolding material to achieve a free-floating monolayer, and 3) assessing monolayer response to appropriately applied forces using image analysis techniques in order to quantify its deformation and other mechanical properties. This development is anticipated to be useful in numerous biomedical applications as there is a significant lack of devices able to test the mechanical properties of a cell monolayer.

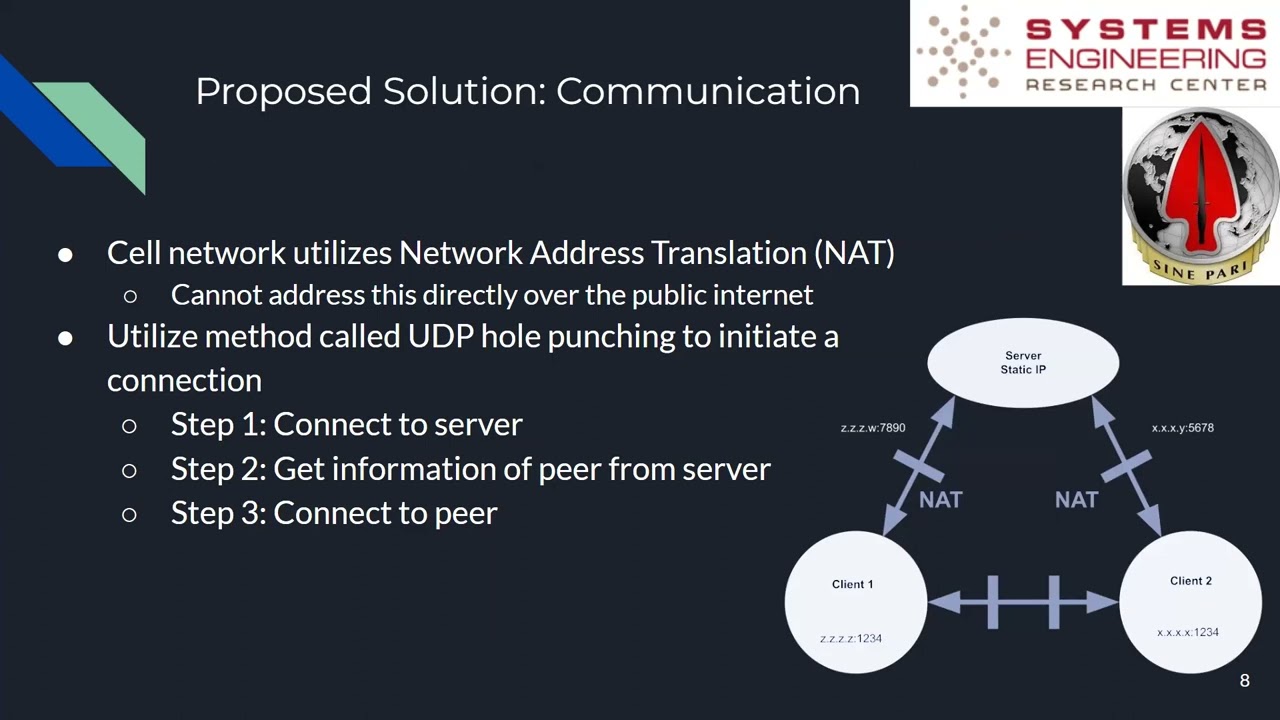

217: Drone Video to Cell Tower

The goal of our project is to develop a transmitter that can be carried on a small drone and exfiltrate drone video to a commercial cell phone network directly through a cellular tower. Transmitting video over commercial cellular networks will allow a drone to successfully transmit data without adversaries detecting any “special” or out-of-the-ordinary signals emitting from the drone. The team first developed a working prototype from off-the-shelf components before designing a custom, streamlined board that utilizes custom software.

218: Engineering Design and Cost Estimate for the Well #6 Hydraulic Network

The goal of our project for the Keweenaw Bay Indian Community is to design a well and its hydraulic system, including a design and cost analysis. This project is necessary because the Keweenaw Bay Tribal Hatchery has a goal to double walleye fry production each year, and is adding in a new 1-acre pond for this purpose that needs to be filled each spring and maintained throughout the production season.

219: Improved Vacuum Sound for Pets

The goal of our project is to modify a BISSELL model vacuum in order to lower its sound pressure level overall by 5 dBA (A-weighted decibel), as well as attenuate "annoying" high frequency peaks. This is being done to reduce the fear of vacuums in pets, which can cause anxiety and stress in pets, mainly dogs. The chosen vacuum is a BISSELL Crosswave Pet Pro. During early stages of testing, we found that our main source of sound was coming from the side exhausts. Our solution method is a custom printed exterior muffler, which will be attached on the side exhausts, to redirect and muffle loud exhaust noises. While we are only working on this specific model, we are hoping that BISSELL can use this idea to improve the sound on many models of vacuums.

220: Improving Consolidated Implantable Satellite Tag for Right Whales by Reducing Local Tissue Trauma

Our team developed surface modifications to telemetry tags for whales, to improve tissue integration and/or minimize potential for localized infection or tissue trauma. The designed modifications need to integrate as part of tags currently in use in the field, but should also be fundamentally be applicable to any current tag that involves skin penetration. We developed a novel approach to enhance the performance of implantable satellite tags by minimizing tissue damage and increasing tag retention time, determined by metrics developed by the team.

221: Instrument Laser Weld Characterization & Testing

The goal of laser weld characterization and testing is to solidify the use of laser weld tactics in the use of medical instrumentation. The project’s main purpose is to focus on the forces of shear and torsion in two main weld types: an edge and pin weld. The team designed prototypes that focus the forces from human use on the instrument at the site of the laser weld, in order to test shear and torsional loads.

222: Kohler Engine Flow Bench

Our goal is to be able to automatically preform pressure and flow sweeps while data logging the results of cylinder heads and carburetors. This project is currently in the implement and building stage. We are verifying labview integration with all components.

223: Low Cost Power Electronic Controller

Our project goal is to develop a lost-cost and portable alternative to the dSPACE control system used in the Michigan Tech’s SB35 lab located in the EERC building. The dSPACE controller and software package now in use is very expensive and uses a minimal amount of the controller's full functionality. It is also large and cumbersome, requiring a desktop PC and large breakout board to operate. The solution to this issue is to replace the dSPACE system with a microcontroller capable of being operated via Simulink, and able to perform the same lab functions as the dSPACE controller.

224: Movable Bookshelf Network

The MTU library has multiple banks of bookshelves on the garden level that are mechanized, collapsing and opening up at the request of the user. We are working with the Blue Marble Security Enterprise to overhaul the system that controls these shelves to be more cost effective. Our team is responsible for networking and communication between the shelves in addition to error reporting through an LCD screen. Largely, we are developing all of the software these shelves will be running.

225: Equipment Checkout Station

Our objective is to eliminate the need for faculty in the ECE Department at Michigan Tech to manually enter student and lab equipment information. We are developing a system that utilizes barcode scanners, which directly enter the data into an existing ECE Department database.

226: Peripheral Interventional Stent Deployment System Handle Evolution

Our team was tasked with reverse engineering and redesigning the Peripheral Interventional Stent Deployment System Handle, the system responsible for deploying a self-expanding stent into the superficial femoral artery. Our redesign optimized cost effectiveness and maximization of deployment length for longer stents compared to both the original model and those of competitors. The project included multiple prototype models for our two main concepts to retract the deployment sheath from over the stent: one utilizing a telescoping rod and the other utilizing a pulley system.

227: Physiological Sensing Using a Smart Port-a-Cath

The goal of this project is to transform a standard port-a-cath into a smart implantable device with the ability to measure common physiological readings while maintaining original functionality. These measurements are achieved through MEMs sensors and a printed circuit board (PCB) incorporated onto the physical port and catheter. The purpose of this device is to allow for remote noninvasive monitoring of cancer patients. Physiological measurements are recorded and uploaded via BLE to an app which will then be accessible by the patients' provider. This project, currently in phase one, involves designing and assembling the PCB, integrating it into a titanium 3D printed port, and evaluating its performance within a phantom environment similar to that of the vena cava.

228: Quantification and Mitigation of Boron from Recycled Steel in Cast Iron

The goal of this quantification and mitigation of boron project is to discover possible options to decrease boron in a cheap, effective manner when the current options are not sustainable for companies in the long term. This will decrease the metal waste from industry if boron can be expelled along with increasing material and mechanical properties of the metal sold to customers. Our team has been working with potential flux materials to trap the boron and discard it from the molten metal. We have been completing multiple experiments to analyze the material properties and elemental changes within our chosen flux material.

229: Quantification of Ambulation for Parkinson’s Disease Patients

The objective of this project is to create a sensing technology that can monitor effectiveness of the treatment a Parkinson’s Disease patient is receiving. The main focus of the device will be to analyze the gait of the patient and quantify the results back to the clinician so they can look over the readings of the device. It will be used in conjunction with Medtronic Deep Brain Stimulation (DBS) treatment and used during clinical visits. As a team, we quantified movement metrics for testing of both the wearable and walkable devices. The wearable device is a sensor on each foot and the walkable device is a mat with many sensors.

230: Real Time Surface-Mounted System for Lake Water Quality and Ice Monitoring

The goal of our project is to develop an inexpensive network of water quality monitoring systems, including an array of sensors connected to an IOT. The main purpose of this network is to allow greater access to water quality data to combat environmental hazards such as stamp sands, invasive species, and pollution. This project is currently in its development phase. In this phase the team is assembling the prototype system using a set of Arduinos and sensors that will be tested in a lab setting to verify the system concepts.

231: Renewable Energy-Powered Portable Plastic Waste Breakdown Machine

The goal of our project is to create a machine that can be transported to substations, allowing crews to produce a usable product out of the plastic waste available on the site. It has entailed extensive research regarding what types of materials among those present in common substation waste are effective to use in which ways. The team has designed the layout of the machine to follow a sequential process that ends with granulated waste being injection molded into promotional material. Testing of the essential components in this process is underway, with a prototype predicted to be finished by design expo.

232: Shot Sleeve Re-design for Steel High Pressure Die Casting (HPDC)

High pressure die casting, HPDC, is a method traditionally used for the rapid casting of aluminum (Al) alloys into complex shapes, and recently there is garnered interest in using this process for steel alloys. HPDC is usually done with H13 steel as the shot sleeve and attempting to do the same HPDC process with stainless steel alloys, resulted in the failure of the H13 shot sleeve. To mitigate this predicted premature failure, an investigation of different ceramic materials to use as a liner inside the shot sleeve was performed.

233: Social Engineering for High School Students

The goal of our project is to develop and deliver social engineering education for high school students in the local area. Through social engineering education, we aim to spread awareness on one of the most common cybersecurity threats, as well as provide resources for reporting the threat and promoting safe practices when emailing, browsing the web, engaging in social media, and answering calls and texts.

234: The Effect of Alloying Composition and Casting Parameters on the Castability and Anodization of Aluminum

The goal of this project is to produce an aluminum alloy that can be gravity die-cast and anodized. This alloy will be used for the purpose of consumer electronics, such as in the cases of fitness bands and e-readers. For this reason, the alloy must be able to produce thin-walled castings with sufficient strength and elongation to survive wear and tear from daily use. Because Amazon’s incumbent alloy contains silicon for fluidity and strength, which cannot be anodized, the focus of this project is to limit the content of silicon in the alloy while maintaining sufficient fluidity and strength.

235: The Effects of Soybean Oil in Reclaimed Asphalt Pavement for Pavement Rejuvenation

The goal of this project is to assess the effects of soybean oil on 100% reclaimed asphalt pavement (RAP). By implementing cold-compaction methods, RAP, and soybean oil, it is possible to create an economical and environmentally friendly alternative to conventional asphalt paving. Additionally, this project seeks to identify the ideal oil additive percentage by utilizing cracking and rutting tests. In doing so, a creative, yet realistic asphalt mixture can be produced and tested in the field.

236: Updating and Upgrading Labs for Wireless System Administration

The goal of our project is to analyze the lab content of SAT3820 to find outdated and depreciated content and upgrade or replace it as needed. This includes fixing and altering existing labs as well as writing a new curriculum to utilize the array of Ubiquiti radios that were recently donated to the program. The goal of the new lab material is to bring more industry relevant content into the lab space and give wireless students the chance to learn hands-on, practical skills that they can carry on into the workplace. This project is currently in its second phase. In this phase the team is deploying new and altered lab material and receiving feedback from students.

237: Utilizing Motor Oil to Rejuvenate RAP Materials

The ultimate goal of this research project is to determine if there is an economical and functional way to create an asphalt mixture using 100% recycled asphalt pavement (RAP) and waste engine oil (WEO). Both of these components are waste products that do not always get recycled and sometimes end up polluting the environment. Creating an asphalt mixture using these two entities could kill two birds with one stone. It would reduce pollution by providing a use for RAP and WEO, and it would be a good option for various types of road construction, improvement or reconstruction.

238: Vehicle Penetration Test

Our project goal is to investigate the possibility of vulnerabilities with modern automotives. The project focused on the use of data transmissions used by the vehicle and attempting to exploit any vulnerabilities that are identified. Such vulnerabilities involved WiFi, Radio Frequencies, and CAN Bus transmissions. We have finished our testing phase and have found and exploited vulnerabilities in the Radio Frequency transmissions from the Vehicle Car Fobs. However, there is more room to investigate different transmission types in the future.

239: Voice Spoofing Countermeasure for Voice-Controlled Systems Using Deep Learning

The goal of our project is to create a protected system that uses primarily voice for authentication, rather than a traditional text password. We developed a Graphic User Interface that takes sound as an input and predicts whether or not a user is authorized to access our system based solely on the characteristics of their voice. In order to accomplish this, we are training a machine learning model for speaker classification using recorded samples of each of our voices. We have also used online AI software to create deep-fake voice lines for each of our voices, which will be used to test how our voice recognition responds to potential cyber-attacks that use fake voices to try and gain unauthorized access to a system such as ours.

240: Waterfowl Retrieval System

Our project goal is to create a replacement for a dog in order to retrieve downed waterfowl in areas that are too dangerous due to alligators or other animals that pose a threat to the life of a dog. This design must be innovative as well as implement partial autonomy while successfully completing the task of bringing ducks back to a hunter.

241: Wire Arc Additive Manufacturing and Heat Treatment of Al-Sc-Zr Alloys

Wire arc additive manufacturing and heat treatment of Al-Sc-Zr alloys

Wire Arc Additive Manufacturing (WAAM) is an additive manufacturing process that allows for lower waste, energy requirements, and costs than traditional subtractive manufacturing. Aluminum WAAM is typically performed using standard aluminum welding filler wire alloys, which cannot be strengthened through heat treatment. The addition of Scandium and Zirconium allows the alloy to be heat-treatable while significantly improving the strength of the alloy. Our project seeks to understand the heat treat responses of a new aluminum alloy design by Hobart Brothers specifically for the creation of heat-treatable WAAM parts.

242: Wireless Tail Lights

The goal of the Wireless Tail Lights is to create a quick, easy, and temporary tail light solution for trailers that have broken, degraded, or no tail lights so that they can drive safely on the road. The project is designed with off the shelf parts and was made so it can be accustomed to many different types of trailers.

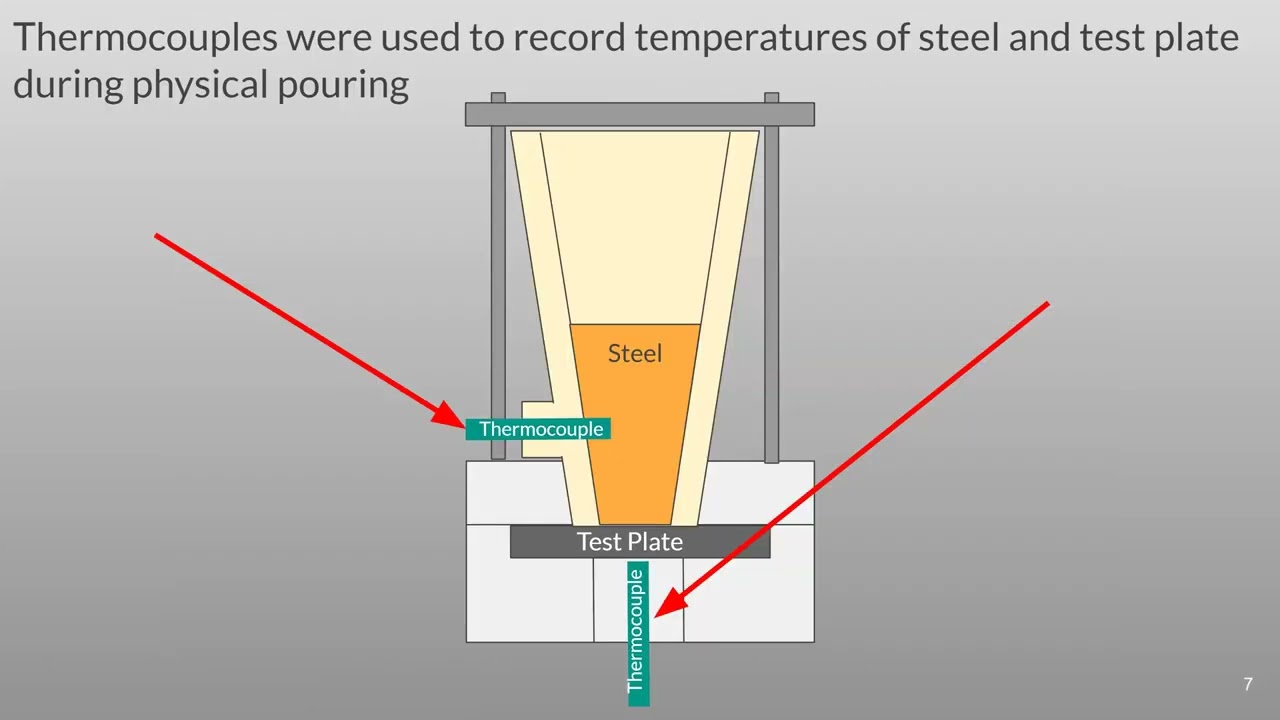

243: 4.0 Consulting

The purpose of team Industry 4.0 is to collect temperature data during the pouring, casting, and testing process in the Michigan Tech foundry. The driving force behind this project is to optimize the use of the foundry data collection for students, staff, and researchers. In this project, the team installed network highways for data to travel while also encrypting data for security. This network installation allowed our team to utilize IoT technology to gather real-time data with tools like an Arduino while syncing to the cloud. With the utilization of IoT devices, we were able to provide ease of access to data through the synchronization of these tools.